Supplied By www.heating spares.co Tel. 0161 620 6677

29

-

The operation of the boiler including

the use and adjustment of ALL system

controls which should be fully explained

to the Householder This then ensures the

greatest possible fuel economy consistent

with household requirements of both

heating and hot water consumptions.

Advise the User of the precautions

necessary to prevent damage to the

system, and to the building, in the event

of the system remaining inoperative during

frost

conditions.

-

Explain and demonstrate the function of

time and temperature controls, neon lights

radiator valves etc. for the economic use

of the system.

- If an optional time clock is fi tted, then draw

attention to the timeclock User’s

Instructions and hand them to the

Householder.

- Stress importance of regular servicing

by a qualifi ed Heating Engineer and that a

comprehensive service should be carried

out AT LEAST ONCE A YEAR.

SECTION 7

SERVICING INSTRUCTIONS

Ravenheat are a member of the Benchmark initia-

tive and fully supports the aims of the programme

Benchmark has instructed to improve the stan-

dards of installation and commissioning of central

heating systems in the UK and to encourage in

the regular servicing of all central heating sy-

stems to ensure safety and effi ciency.

7.1 SERVICING

7.1.1

To ensure continued effi

cient operation of

the appliance it is necessary to carry out

servicing and cleaning at regular intervals

The frequency of cleaning will depend

upon the particular installation conditions

and usage but in general, once per year

should be adequate.

WARNING:

Before the start of any servicing or replacement

of components always isolate electricity

supply to the appliance and always turn off

the appliance gas supply at the gas

service

cock.

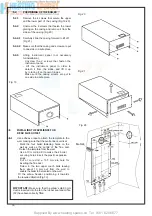

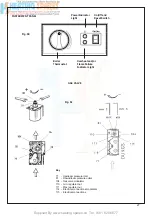

Data badge position - lower left hand sub

frame.

- The following notes apply to the appliance

and its controls but it should be remembered

that attention must also be paid to the

heating and hot water circuits with special

attention to radiator valves, thermostats,

clocks, leaking hot water taps etc.

- Where it is necessary to replace a

gasket that relies on adhesive for

securing - this adhesive will be supplied

with the gasket as a spare item.

- In all cases prior to servicing, remove the

outer case (sect. 5.4).

Operate the appliance by turning

the boiler thermostat up and down and

observe the main burner.

- Check that the fl ame covers all the fl ame

ports and is of a light blue colour Yellow

fl ames and excessive lifting of fl ames

indicate poor combustion.

-

IMPORTANT:

After completing any

servicing or replacement of gas carrying

components it is essential that a test for

gas soundness is always carried out along

with functional checks in operation.

7.2

TO INSPECT AND CLEAN

THE

APPLIANCE

7.2.1

Before carrying out cleaning operation, cover

the electrical control panel with a piece of

waterproof material to protect it from debris.

7.2.2

Inspect the heat exchanger for any blockage

Deposits of any material should be brushed

away using a soft brush.

NOTE:

Do not use brushes with metallic

bristles.

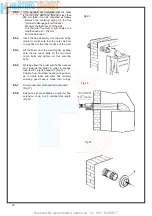

7.2.3

Examine internal pipe-work connections and

automatic air vent for any water leaks.

Rectify if necessary.

7.2.4

Examine the combustion chamber insulating

material and renew if damaged.

7.2.5

Remove and examine the burner

injector clean or renew, as necessary.

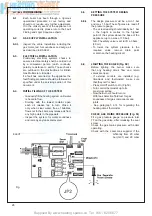

7.2.5.1

Inspect the burner and remove any

deposit with a soft brush. Check the electrodes

for damage or deterioration, clean or

renew as necessary.

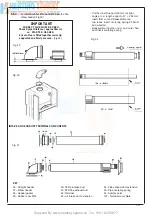

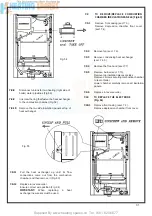

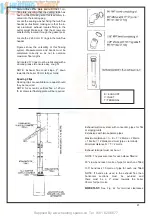

Ensure that the spark gaps are correct to

dimensions specifi ed in Fig.52.

7.2.6

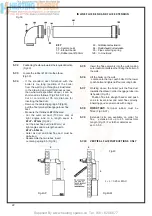

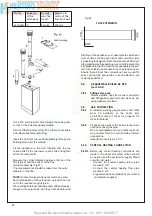

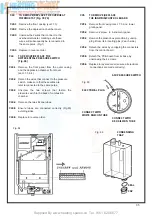

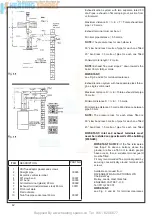

Inspect the secondary condensate heat

exchanger.Deposits can be cleared by

removing

and

fl ushing out the exchanger.

Inspect the siphonic condensate trap for a

blockage. Any deposits should be fl ushed out

(Fig.

90).

Fig.52

Summary of Contents for HE Primary AAA

Page 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Page 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Page 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...