Winter Use

(See Para. re: Firebrick Positions

The maximum boiler output obtainable burning solid fuel at the

optimum burning rate - with the cooker/boiler damper knob at

H

and the boiler thermostat at No.8 - is 16.12kW (55,000 Btu/h).

This will provide for 29.89m of radiator surface and pipework

plus domestic hot water or 32.24m of radiator surface and

pipework only. The recommended heating surfaces indicated

are based on an average heat emission of 0.5kW/m (160

Btu/h/ft). When cooking only, with the cooker/boiler damper

knob at

C

and oven at a steady 230ÞC (450ÞF), the water

output reduces to 5.6kW (19,000 Btu/h). Overnight banking with

the cooker/boiler damper knob at

C

will produce 2.3kW (8,000

Btu/h) of hot water from the boiler.

Summer Use

See para re: Firebrick Positions

With the cooker/boiler damper knob at

C

and the oven

temperature maintained at a steady 200ÞC (390ÞF) the hot

water output from the boiler will be 3.1kW (10,500 Btu/h).

Overnight banking with the cooker/boiler damper knob at

C

will

produce 1.9kW (6,900 Btu/h) of hot water from the boiler.

Winter Use:

To obtain the optimum burning rate with the wood

burning fuels only, a grate baffle should be located on the top

face of the reciprocating bars, at the rear of the firebox.

See diagram.

Grate riddling is not required when burning wood where poking

will normally suffice.

Always remove this grate baffle when burning solid fuels.

See para. re: Firebrick Positions

The maximum boiler output obtainable burning wood logs at the

optimum burning rate - with the cooker/boiler damper knob at

H

and the boiler thermostat at No.8 - is 10.26kW (35,000 Btu/h).

This will provide for 18.17m

2

(194ft

2

) of radiator surface and

pipework plus domestic hot water 20.52m

2

(219ft

2

) of radiator

surface and pipework only. Overnight banking with the

cooker/boiler damper knob at

C

will produce 1.46kW (5,000

Btu/h) of hot water from the boiler.

Summer Use

See para. re: Firebrick Positions

With the cooker/boiler damper knob at

C

and the oven

maintained at roasting temperature the hot water output from

the boiler will be 2.6kW (9,000 Btu/h) of hot water from the

boiler.

Overnight banking with the cooker/boiler damper knob at

C

will

produce 1.46kW (5,000 Btu/h) of hot water from the boiler.

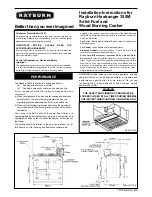

The non-combustible hearth must be solid and level and

together with the walls adjacent to the cooker and chimney,

conform to current Building Regulations.

The cooker and chimney flue installation should be in

accordance with the relevant recommendations of the British

Codes of Practice BS 8303, BS 6461 Part 1 and BS 7566 Parts

1 to 4 respectively and the central heating system to BS 5449

Part 1. The boiler installation section must also be in

accordance with the byelaws of the local Water Undertaking,

Regulations for the Electrical Equipment of Buildings -

published by the Institute of Electrical Engineers and any

relevant requirements of the Local Authority.

Ensure that any electrical wiring is correctly earthed.

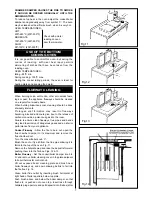

When the cooker is installed in a recess it must be

‘freestanding’ and not built-in solid at the sides. Ensure that any

combustible material e.g. kitchen furniture is spaced away from

the cooker to the recommended distances. See Fig. 1.

Tiling

Where the cooker is to stand in a recess or against a wall which

is to be tiled,

in no circumstances should the tiles overlap

the cooker top plate

.

From 200mm thick non-combustible or new recesses, an

opening of 1,080mm wide minimum, by 343mm deep minimum

and 1,680mm high minimum from floor is recommended.

NOTE (SEE FIG. 1): PLEASE NOTE IT IS ADVISABLE TO

CHECK THE SIZE/WIDTH OF YOUR APPLIANCE BEFORE

FINALLY FIXING ANY KITCHEN UNITS SINCE ENAMELLED

CAST IRON CAN VARY IN SIZE.

PREPARATION OF SITE

COOKER POSITION

Fig.1

2

RATINGS - Burning Solid Fuel

RATINGS - Burning Wood

DESN 510279 B

BUILDERS OPENING