quarter of a turn.

Set the boiler thermostat knob to its minimum setting and

close the flue chamber damper plate to No. 1 setting. Set

the cooker/boiler chamber knob to ‘C’ to obtain optimum

heat into oven and hot plate.

NOTE: THE BEST POSITION FOR THE FLUE

CHAMBER DAMPER CAN BE FOUND ONLY BY

EXPERIMENT BUT ALWAYS TRY THE LOW SETTING

FIRST.

In the morning, open the spinwheel three complete turns,

the flue chamber damper to maximum and riddle the fire.

When it is burning brightly, close the flue chamber

damper, but do not refuel before use if the hotplate is

required immediately.

All Fuels.

Set the cooker/boiler damper knob ‘H’.

Close spinwheel.

To regulate burning, set the boiler thermostat knob to ‘8’

(high) or minimum rate ‘1’ (low).

Adjust as required to suit desired water heating.

Overnight banking and daytime slow burning should be

obtained with the boiler thermostat knob set at ‘1’ to give

extended burning.

Woodburning

Some wood are more difficult to burn therefore it may be

necessary to open the spinwheel in addition to the

thermostat to obtain the desired results. The spinwheel

must be closed as appropriate.

Solid Fuel

The appliance may be operated overnight for the

purpose of selected central heating when inclement

weather conditions occur.

Set the cooker/boiler damper knob to ‘H’ after refuelling

etc. and the boiler thermostat knob to No. 2 with the flue

chamber damper set at minimum. The spinwheel should

be closed and about four radiators can be run overnight

under these conditions.

NOTE: THE HOTPLATE AND OVEN TEMPERATURE

WILL BE CONSIDERABLY LOWER AND EXTENDED

TIME WILL BE NEEDED TO HEAT UP THESE

FEATURES. DO NOT FORGET TO RE-SET THE

COOKER/BOILER KNOB TO ‘C’ FOR COOKING

AFTER OVERNIGHT USE.

Wood

The appliance is designed for continuous slumbering

overnight for up to a maximum of 12 hours depending on

the type of dry wood being used. Last thing at night, open

the flue chamber damper. de-ash the fire, empty the

ashpan and fully refuel.

Ensure that the firebox and ashpit door are securely

closed

, close the spinwheel tight and the flue chamber

damper is set to No.1.

Set the boiler thermostat knob to its minimum setting

and the front damper knob to ‘c’.

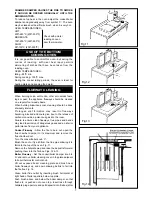

Turn the flue dilution lever (See Fig. 7) from left to right

hand so that the flue chamber door opens at the bottom

and minimise burning rates.

NOTE: THE PRECISE AMOUNT OF OPENING

DEPENDS ON THE CHIMNEY DRAUGHT, THE

TYPE/CONDITION OF WOOD TO BE BURNT AND

THIS MAY TAKE 2 OR 3 DAYS TO ASCERTAIN

.

1. If the fuel in the firebox is exhausted prematurely, the

overnight chimney draught must be reduced by

increasing the opening setting of the flue chamber

door, using the flue dilution lever.

2. If the fuel does not burn but ‘dies out, the draught

should be increased by reducing the opening setting.

of the flue chamber door, using the flue dilution lever.

Following overnight banking, the flue chamber door must

be closed, the spinwheel and flue chamber damper

opened and the fire refuelled.

Immediately the new fuel has caught alight, riddle the fire

and close the flue chamber damper.

NOTE: BUILD-UP OF CREOSOTE DEPOSITS IN THE

FLUE AND CHIMNEY CAN IN TIME, LEAD TO

CHIMNEY FIRE.

THESE DEPOSITS CAN BE PREVENTED BY THE

REGULAR USE OF A PROPRIETARY BRAND OF

CHEMICAL CREOSOTE REMOVE CHIMNEY

CLEANER SUCH AS “ATTACK” WHICH REDUCES

THE ADHESION STRENGTH OF THE CREOSOTE

DEPOSITS, CAUSING THEM TO FAIL.

IMPORTANT: CHEMICAL CLEANERS MUST NOT BE

CONSIDERED AS AN ALTERNATIVE TO CHIMNEY

SWEEPING, ONLY AS SUPPLEMENTARY.

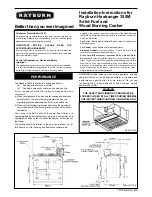

Against Thermostat knob settings with Cooker/Boiler

Damper at ‘H’ and Spinwheel closed.

Thermostat Setting No.

Water Temperature

(APPROXIMATE)

1

46ÞC (115ºF)

3

54.5ÞC (130ºF)

5

65.5ÞC (150ºF)

8

80ÞC (176ºF)

a) Using the cooker boiler to provide heat for domestic

hot water and radiators in the winter, a boiler thermostat

setting at No.8 is recommended.

b) Using the cooker boiler for the provision of domestic

hot water only, in the summer, a boiler thermostat setting

of No. 5 is recommended.

NOTE: TO CONSERVE FUEL, ENSURE THE HOT

WATER CYLINDER AND PIPES ARE LAGGED WITH

INSULATION.

BOILER CENTRAL HEATING

THERMOSTAT SETTING

OVERNIGHT CENTRAL HEATING

TYPICAL WATER

TEMPERATURES

OVERNIGHT BANKING

5