resetting cooker/boiler damper knob to ‘C’).

Replace flue chamber door and hotplate plug and riddle

the bottomgrate thoroughly to clear the bottomgrate

ready for relighting.

NOTE: THE APPLIANCE IS DESIGNED AND

INTENDED TO BE UNDER CONTINUOUS FIRING BUT

IF IT IS NOT IN USE ASHPIT AND FLUE CHAMBER

DOORS SHOULD BE LEFT OPEN TO ENSURE FREE

PASSAGE OF AIR THROUGH THE APPLIANCE AND

AVOID CONDENSATION PROBLEMS.

Sweep annually and inspect soot box at 3 monthly

intervals and remove any deposits.

NOTE: SWEEPS BRUSHES MUST BE OF THE TYPE

WITH WIRE CENTRES AND GUIDE WHEELS.

Surface blemishes caused by spillage on the gloss

enamel are easier to remove when the cooker is cool,

and a damp cloth is usually all that is necessary.

This should not be done whilst the cooker is hot.

DO NOT USE ABRASIVE PADS, OVEN CLEANER, OR

CLEANERS CONTAINING CITRIC ACID ON

ENAMELLED SURFACES.

IMPORTANT NOTE:

Aga recommend Vitreous Enamel

Association approved cleaners for cleaning the vitreous

enamelled surfaces of this product.

But they are unsuitable for use on: chrome and stainless

steel components, including the hand-rails and their

brackets.

The insulating covers should be cleaned regularly with a

NON-ABRASIVE mild detergent, applied with a soft

(coarse free) cloth and lightly polished up afterwards with

a soft (coarse free) duster or tissue to bring it back to its

original lustre.

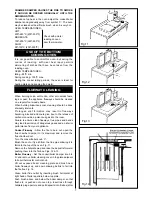

Allow fire to burn out first then open the ashpit door and lift

off the clinker door. Remove dead fuel with hooked poker

into ashpan and then lift up each individual bar, pulling

forward to remove.

NOTE: THERE ARE TWO TYPES OF BARS ASSEMBLED

AND THE REPLACEMENT BARS SHOULD BE

CHECKED AGAINST ‘REPLACED’ BAR BEFORE

REPLACEMENT.

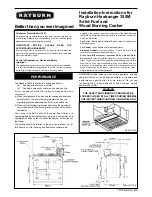

The firebricks fitted to the Rayburn 355M are of first quality

manufacture, and providing the cooker has been installed

and used correctly will have a reasonable life. They are,

however, expendable items and in time will require renewal.

Replacement bricks either in sets or singly can be obtained

from your Rayburn distributor. Always quote the

manufacturing number.

The manufacturing number, which will be found on a brass

plate inside the roasting oven, should be quoted if any

question arises in connection with the Rayburn 355M

Cooker.

The cooker has been designed to provide a satisfactory

supply of domestic hot water with or without a limited

amount of heating with a normal day’s cooking providing the

cooker is kept alight overnight and the system complete with

lagged cylinder conforms to the installation instructions.

Always use a qualified service/heating engineer when

servicing is required.

Properly installed and operated, this cooker will not emit

fumes.

Occasional fumes from de-ashing and re-fuelling may occur

but persistent fume emission must not be tolerated.

If fume emission does persist, then the following immediate

action should be taken:-

a) Open doors and windows to ventilate room.

b) Let the fire out or remove lit fuel from cooker.

c) Check for flue or chimney blockage, and clean if

required.

d) Do not attempt to relight fire until cause of fume has

been identified, and if necessary, seek professional

advice.

TO REPLACE

BOTTOMGRATE BARS

FIREBRICK REPLACEMENT

HOT WATER SERVICE

SERVICING

FUME EMISSION WARNING

8

CLEANING

CHIMNEY SWEEPING