COOKER

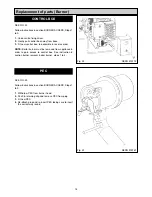

SEE FIG. 10

1.

Remove two socket head screws.

2.

Remove head assembly complete.

3.

Disconnect ignition leads

4.

Remove ignitor assembly, by removing countersunk

screw and clamp.

5.

Unscrew nozzle from its holder with a correctly fitting

tubular spanner to avoid damage to hexagon.

BOILER

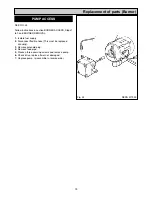

SEE FIG. 10A

1.

Release two countersunk head screws and remove

blast tube.

2.

Remove two screws and slide out nozzle support

cradle c/w ignitor assembly from burner head.

3.

Unscrew nozzle from its holder with a correctly fitting

tubular spanner to avoid damage to hexagon.

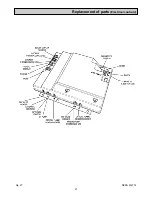

SEE FIG. 11

1.

Replace nozzle with a new one of the same make and

specification.

2.

Ensure that mating faces are clean.

3.

Hold nozzle holder with correct spanner when

tightening nozzle.

4.

Typically finger tight plus 1/4 turn with spanner is

sufficient.

DO NOT OVERTIGHTEN.

5.

Ensure electrode gaps are correct.

11

Burner Servicing

BURNER NOZZLE REMOVAL

BURNER NOZZLE REPLACEMENT

Fig. 11

Fig. 10

DESN 510538

DESN 515766

3mm

Fig. 10A

Summary of Contents for 660

Page 21: ...21 Fig 27 DESN 514774 Replacement of parts Electrical controls ...

Page 22: ...22 Fault Finding Fig 28 Rayburn 600 700 Wiring Diagram 111MB for Individual Satronic boxes ...

Page 23: ...23 Fault Finding Fig 29 Rayburn 600 700 Wiring Diagram 111MB self contained control ...

Page 29: ...Fault Finding 29 Fig 31A DESN 516838 ...

Page 30: ...30 Fault Finding ...

Page 31: ...31 Fault Finding ...

Page 33: ...33 ...

Page 34: ...34 ...

Page 35: ...35 ...