14

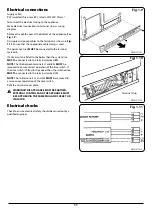

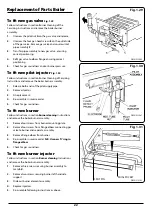

Main burner lighting see

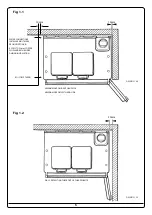

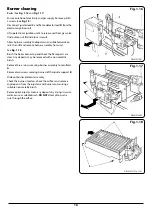

Fig. 1.14

This appliance is fitted with a combustion discharge safety

device which will switch off both main burners in adverse

flue conditions. Before turning on main burners ensure that

the manual reset button, which is located on the right hand

side of the plinth is depressed (

Fig. 1.8

).

Ensure the electricity supply is turned ON and set any

external controls to the ON position.

Turn the boiler thermostat knob to MAX., and the boiler will

ignite.

Turn the cooker thermostat to H, and the cooker burner will

go to full rate.

Check for gas soundness of all leaks with leak detection fluid.

Turn off both burners.

Turn the thermostat knob to the required setting.

The boiler and pump should be run until the system is hot.

Check for water leaks, then flush the system with all manual/

automatic valves open. Upon refilling check the system for

leaks. When all the air has been removed from the water

circuit, the pump and radiators should be balanced to

achieve the correct temperature to drop across the system.

Set any timer room temperature, etc to suit the customer’s

requirements.

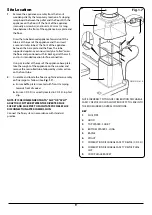

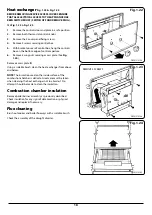

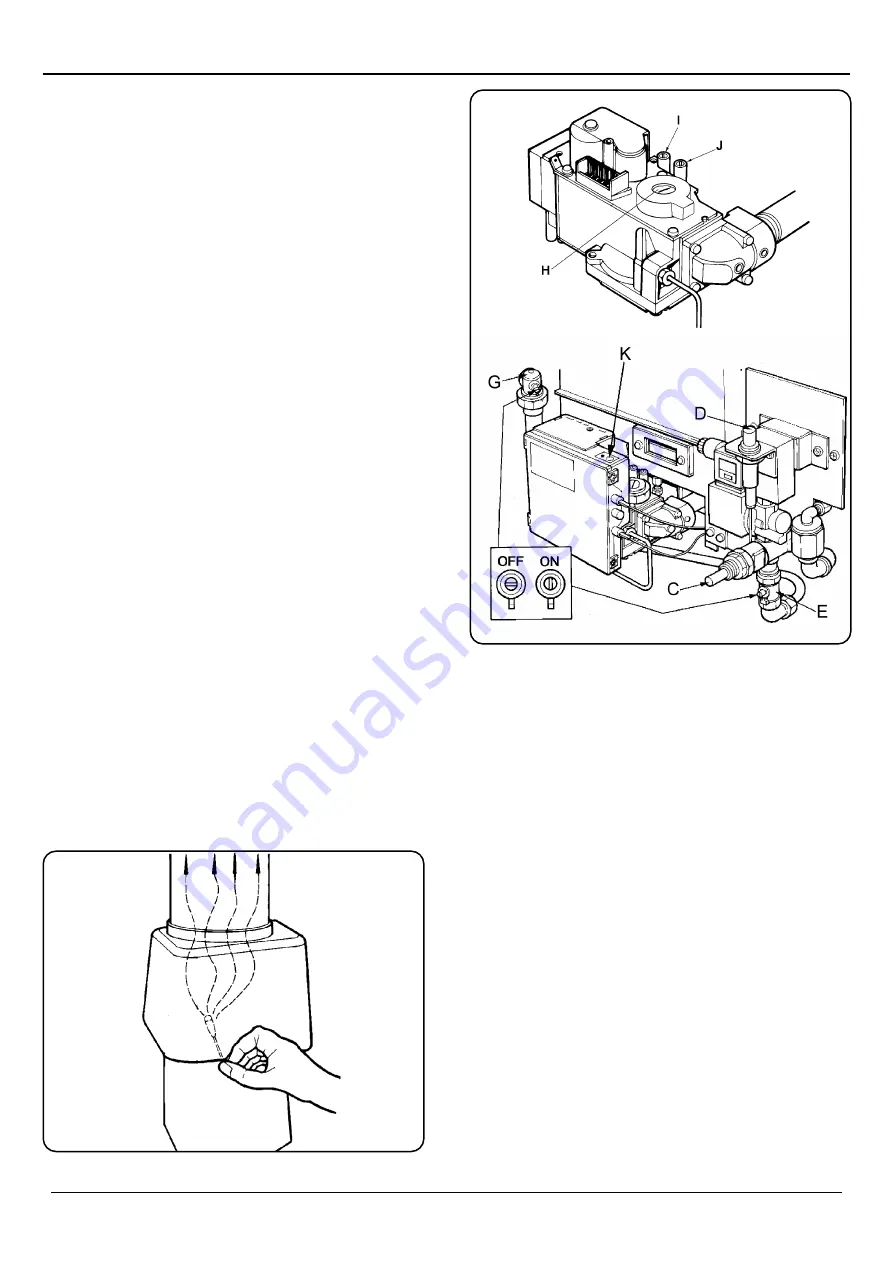

Spillage test

With cooker and boiler burners full on.

A spillage test must be carried out after 5 minutes, as follows:

Light a smoke match and position into the draught diverter

as shown in

Fig. 1.13

. If smoke does not spill back into the

room then the installation is satisfactory. If smoke is drawn

back into the room leave burners on for further 10 minutes

and check again.

n

WARNING: IF THE SMOKE SPILLS BACK INTO THE

ROOM, DISCONNECT THE APPLIANCE AND SEEK

EXPERT ADVICE.

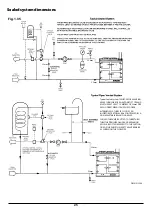

Commissioning

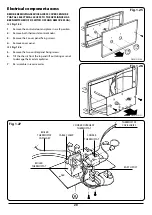

DESN 517111

DESN 512964

Fig. 1.14

Fig. 1.13

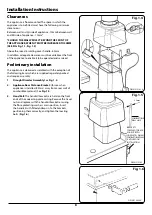

KEY

C - COOKER FLAME FAILURE OVERRIDE BUTTON

D - PIEZO IGNITION BUTTON - COOKER

E - GAS COCK - COOKER

G - GAS COCK - BOILER

H - BOILER BURNER PRESSURE REGULATOR ADJUSTMENT

SCREW

I - PRESSURE TEST NIPPLE INLET

J - PRESSURE TEST NIPPLE - BOILER BURNER

K - BOILER BURNER RESET

DESN 512965