4

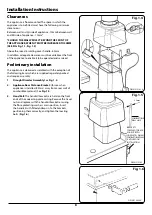

Location

The appliance must be installed on a solid level floor or base

of incombustible material which is capable of supporting the

total weight.

The location chosen for the appliance must permit

installation and the provision of a satisfactory flue and an

adequate air supply. The location must also provide space for

servicing and air circulation around the appliance.

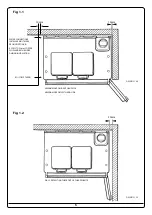

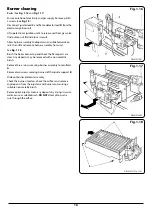

Between wall and LH side of appliance

10mm Between

wall and RH side of appliance

10mm*

*SHOULD THE WALL PROJECT BEYOND THE FRONT OF

THE APPLIANCE, WHEN IT MUST BE INCREASED TO 50MM

(SEE FIG. Fig. 1.1, Fig. 1.2).*

Above the raised insulating cover handle 60mm

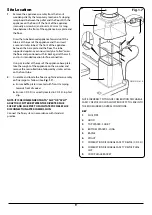

NOTE: GAS AND WATER CONNECTIONS ARE LOCATED

ON THE LH SIDE OF THE APPLIANCE. INSTALLERS MUST

MAKE PROVISION FOR ACCESS TO THESE CONNECTIONS

DURING INSTALLATION.

In addition, adequate clearance must be available at the

front of the appliance to enable it to be operated and

serviced. Flue pipes and fittings must not be closer than

25mm to combustible materials and where passing through

a combustible partition such as a ceiling or roof, must be

enclosed in a non-combustible sleeve providing an air space

of at least 25mm.

Spaces around flue pipes passing through walls or floors

should be sealed against the passage of smoke and flame.

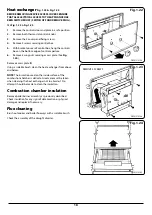

Where the cooker is to stand in a recess or against a wall

which is to be tiled,

in no circumstances should the tiles

overlap the cooker top plate.

NOTE: SMOKE/SMELL EMITTED DURING INITIAL USAGE.

Some parts of the cooker have been coated with a light

covering of protective oil. During initial operation of the

cooker, this may cause smoke/smell to be emitted and is

normal and not a fault with the appliance, it is therefore

advisable to open doors and or windows to allow for

ventilation. Lift the insulating lids to prevent staining the

linings.

Gas supply

Pipework from the meter to the appliance must be of

adequate size. It is recommended that ø22mm minimum

diameter copper tubing is used. Do not use pipes of a smaller

size than the appliance gas connection. The complete

installation must be tested for soundness and purged in

accordance with the regulations in force.

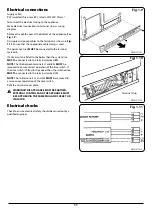

Electrical supply

External wiring must be correctly earthed, polarised and

in accordance with current regulations. The main supply

required is 230V, 50Hz fused at 3A.

NOTE

: The method of connection to the electricity supply

must facilitate complete electrical isolation of the appliance,

preferably by the use of a fused three pin plug and

unswitched shuttered outlet. Alternatively, connection may

be made by a via a fused double-pole isolator with a contact

separation of at least 3mm in all poles and serving the

appliance and system control only.

Site Requirements