18

Checks to ensure electrical safety should be carried out

by a competent person.

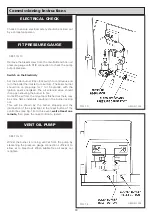

- SEE FIG. 13

Remove the bleed screw from the manifold and fit an oil

pressure gauge with R1/8 connection to check the pump

output pressure.

Switch on the Electricity

Set the boiler burner time clock switch to continuous and

turn the boiler thermostat to maximum. The boiler burner

should run on pre-purge for 7 to 15 seconds, with the

ignition spark energised. The oil solenoid valve should

then open allowing the burner to fire.

Until all the air from the oil pump is flushed out there may

be some flame instability resulting in the burner locking

out.

This will be shown by the burner stopping and the

illumination of the signal light in the reset button of the

control box (see Fig. 14). In this event,

wait at least one

minute,

then press the re-set button to restart.

- SEE FIG. 13

Whilst the burner is running, vent air from the pump by

slackening the pressure gauge connection sufficient to

allow air to bleed out. When bubble free oil seeps out

retighten.

Commissioning Instructions

FIT PRESSURE GAUGE

ELECTRICAL CHECK

VENT OIL PUMP

FIG. 13

FIG. 14

DESN 511235

DESN 511236

Summary of Contents for Heatranger 480D

Page 8: ...Site requirements 7 DESN 510519 FIG 1...

Page 14: ...13 Site requirements FIG 4...

Page 23: ...Sealed Systems 22...

Page 24: ...23...

Page 25: ...24...