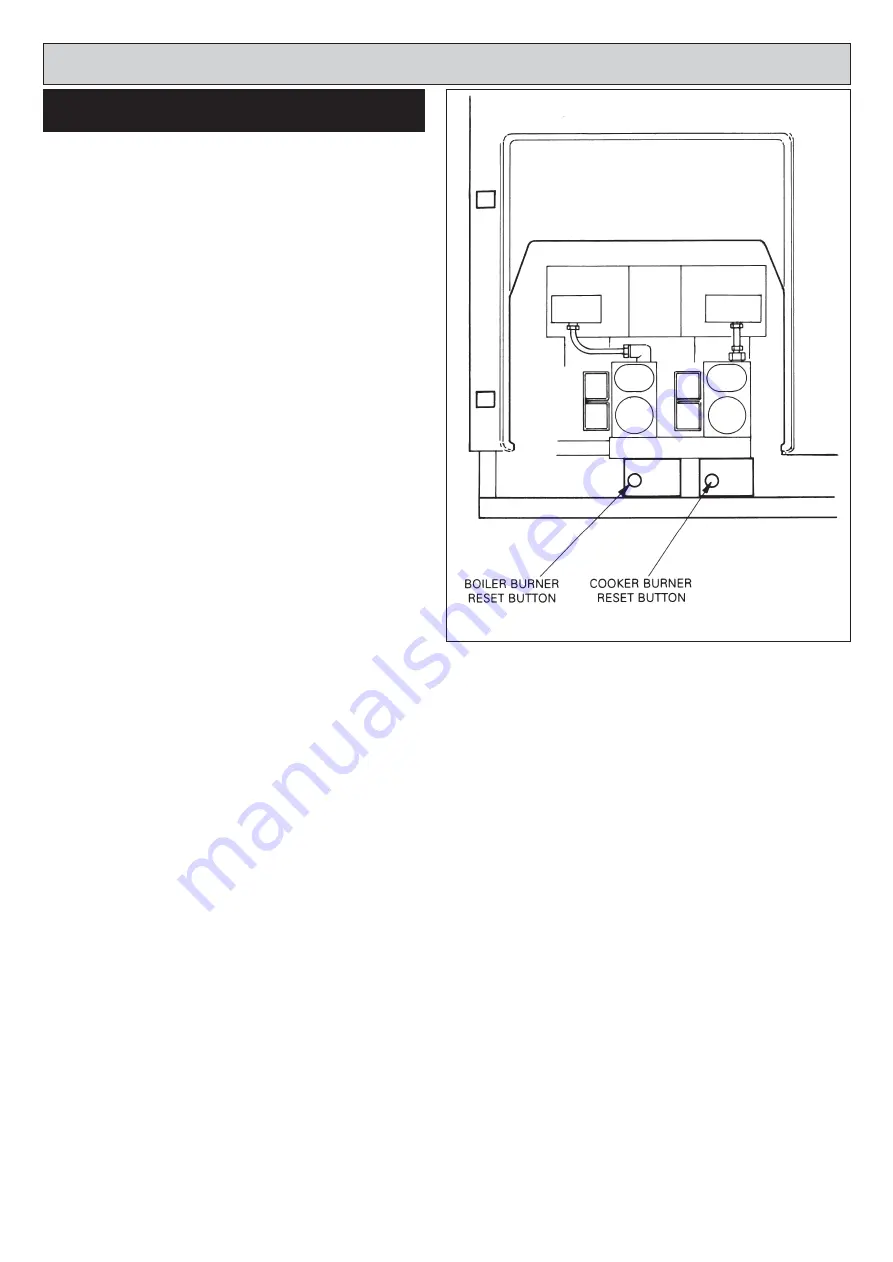

SEE FIG. 8

Switch on electricity supply

BOILER BURNER

Set boiler burner clock to continuous and turn the boiler

thermostat to max. allowing the burner to start, the

burner should go to lockout after the expiry of the ignition

safety time. Lockout is indicated by illumination of the

control box reset button.

IN THE EVENT OF LOCKOUT

WAIT AT LEAST ONE MINUTE

then press the reset

button.

COOKER BURNER

Follow procedure as above for boiler burner.

BOILER BURNER

Reset the control box, open the gas inlet cock, allowing

the burner to restart.

When the burner is in ‘run’ condition close the inlet gas

cock. When the flame is extinguished the gas valves

solenoids on the burner should be de-energised almost

immediately.

The control will then allow one restart attempt and should

go to lockout after the expiry of the safety time.

COOKER BURNER

Repeat procedure as above for the boiler burner.

FIG. 8

DESN 511122

TEST BURNERS ON DRY RUN

(NO GAS)

8

Re-commissioning

Summary of Contents for Heatranger 480GB

Page 15: ...Replacement of parts Electrical FIG 20 DESN 511140 14...

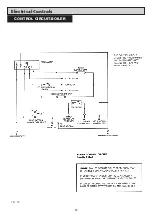

Page 23: ...Electrical Controls 22 CONTROL CIRCUIT BOILER FIG 30...

Page 24: ...Electrical Controls 23 CONTROL CIRCUIT COOKER FIG 31...

Page 25: ...Electrical Controls 24 WIRING DIAGRAM BURNER ONLY FIG 32...

Page 26: ...25 WIRING DIAGRAM APPLIANCE Electrical Controls FIG 33...

Page 30: ...29...

Page 31: ...30...

Page 32: ......

Page 33: ......