35

OIL STORAGE TANKS

Oil storage tanks made of steel and all connecting equipment

(eg: filling pipes and vent pipes) should comply with B.S.

799 Part 5. Galvanised steel must not be used. Polyethylene

(Plastic) tanks should comply with OFTEC standard OFS T100

and or equivalent. Oil should never be stored in translucent

plastic containers.

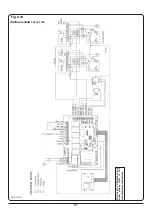

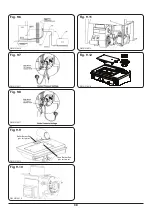

An isolating valve should be fitted at the tank outlet, in an

accessible position so that the oil supply to the appliance can

be shut off if required. This isolating valve must be of a type

suitable for use with oil. (See

&

In order to enable the sediment and water to be removed

from tanks a drain valve should be fitted. Oil storage tank

support must be carried out in accordance with the tank

manufactures recommendations. Tanks should be located

in the most un-obstructive position possible having taken

safety, filling, maintenance and the need, if any, to provide a

head of oil for the burner into consideration.

FUELS

THE RECOMMENDED FUEL IS KEROSENE 28 SECOND

VISCOSITY FUEL OIL.

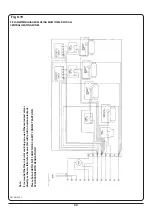

FUEL SUPPLY LINE

The oil supply line from the oil storage tank to the appliance

should be of an approved and suitable pipe with a minimum

internal diameter of 9mm (3/8”) and connected to the oil inlet

connection located at the cooker left hand side.

Oil supply pipes are normally run in annealed copper tube

complying to B.S. E.N. 1057. It can be obtained in coil or half

hard form for use with bending machines. This pipe can

also be obtained with protective plastic sheathing applied.

Fittings for copper pipe should be compression of the

flared manipulative type to B.S. 864: Part 2 1983. Steel pipes

complying with B.S. 1387: 1985, if used, must be protected

from corrosion. Galvanised pipe and fittings must not be

used.

Screwed joints must only be made with tapered threads

complying with B.S. 1740: Part 1: 1971.

Jointing materials must be of types intended for use with oil

fuel. Special petroleum – resisting compounds and PTFE tape

are suitable. External pipes should preferably be run with a

continuous rise towards the direction of flow, so that one can

be vented off. It is important to avoid high points which could

cause air locks.

Exposed lengths of oil supply pipe must be properly

supported by purpose made clips securely fixed in place.

Metal clips formed so as to hold the pipe on to a saddle

are preferred. Consideration should be given to avoiding

routes which expose the pipe to severe chilling which could

cause freezing of the oil. Where pipes are buried, they must

be protected from accidental damage. The use of joints

underground should be avoided if at all possible. If joints

have to be fitted in pipes laid below ground, access to them

must be provided.

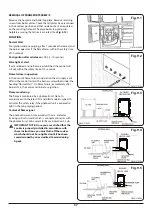

An oil filter (5 - 10 micron) and stop valve must be fitted

to the fuel feed line and located near the supply tank and

facilities should be provided to enable it to be serviced

without draining down the oil supply system. (See

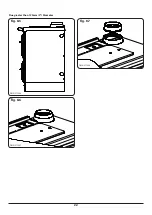

At the point where the oil line enters the building, the oil

line must be fitted with an approved 65ºC remote acting

fire valve, which meets the requirements of B.S. 5410: Part 1,

fitted with the appropriate length of capillary. The heat sensor

phial of the fire valve must be fitted to the clip provided in

the burner compartment. It is absolutely essential that the

fire valve is located externally and is as close as possible to

the appliance. For existing installations where the oil supply

are built into the structure internally, the remote acting

fire valve should be fitted where the oil supply line is first

exposed internally. This type of layout is not recommended

for new installations.

When gravity feed is used (the most common) the minimum

head should not be below 1 meter (3’3”) and the maximum

head should not exceed 6.5 meters (21’ 3”).

NOTE

: The pump is factory set for a single pipe installation

to convert to a two pipe system consult manufacturer’s

instructions.

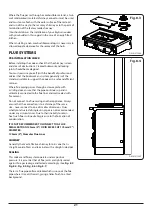

Before connecting the oil supply, secure appliance burner oil

pipes to the base using the T junction (see

&

).

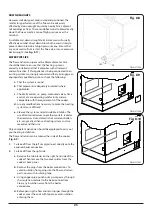

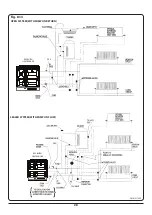

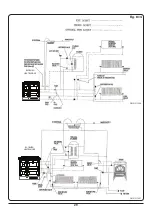

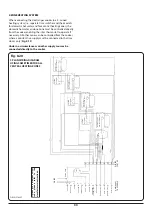

SINGLE PIPE SUPPLY SYSTEM: BOTTOM OF OIL STORAGE

TANK ABOVE BURNER (See

)

Single pipe supply system: Tanks servicing this appliance by

means of a single pipe need to be positioned so that they will

apply the minimum head required 1 meter (3’ 3”) of oil to the

burner when the fuel level is at its lowest point.

Refer to B.S. 5410 to calculate the additional head

requirement relating to pipe length and size.

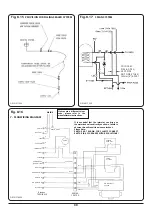

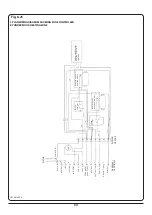

TWO PIPE SUPPLY SYSTEM: BOTTOM OF OIL STORAGE

TANK BELOW OR LEVEL WITH BURNER (see

If the tank base is below the level at which the gravity feed to

the burner can be maintained, a two pipe oil supply system

may be adopted. (See

). The non-return valve in the

supply line of the two pipe system is required to prevent oil

running back from the burner and unpriming the oil pump.

The non-return valve in the return line is only required if the

top of the tank is above the burner. Its purpose is to prevent

oil running back through the burner during maintenance.

SINGLE PIPE SYSTEM: WITH DE-AERATION DEVICE

BOTTOM OF OIL STORAGE TANK BELOW OR LEVEL WITH

):

This system can be used where the tank base is below the

level at which gravity feed to the burner can be maintained

and the burner incorporates an oil pump. The chamber is

9. Fuel Installation