The Rayburn is a floor standing cooker, fired by a gas

burner.

The burner fitted to this appliance has been designed

and constructed exclusively for use with the Rayburn

XT Cooker and MUST not be used on any other

appliances or any other uses.

In the interests of safety all gas appliances should be

installed by competent persons in accordance with the

regulations in force.

Installation Pipes

Pipework from the meter to the appliance must be of

adequate size. It is recommended that a minimum of ø22

mm copper tubing is used to within 1m of the appliance.

A reduction to ø15mm is permissible over the last metre

of the appliance. Do not use pipes of a smaller size than

the appliance gas connection. To avoid undue stress on

pipework and burner, adequate support should be used

when connecting and disconnecting union. The complete

installation must be tested for soundness and purged in

accordance with the regulations in force.

FLUE SAFETY DEVICE

For safety purposes a flue safety device is fitted. This will

only operate in adverse or blocked flue conditions. If the

switch has operated, it should be pushed in, to reset. If

this problem persists it is necessary to determine and

rectify the cause. If it is found necessary to reset more

than once this may indicate a flue blockage.

The appliance is floor mounted and must be installed on

a solid floor or base of non-combustible material which is

capable of supporting the total weight.

The location chosen for the appliance must permit the

installation and the provision of a satisfactory flue and an

adequate air supply. The location must also provide

adequate space for servicing and for air circulation around

the appliance. See “Installation of the Appliance”.

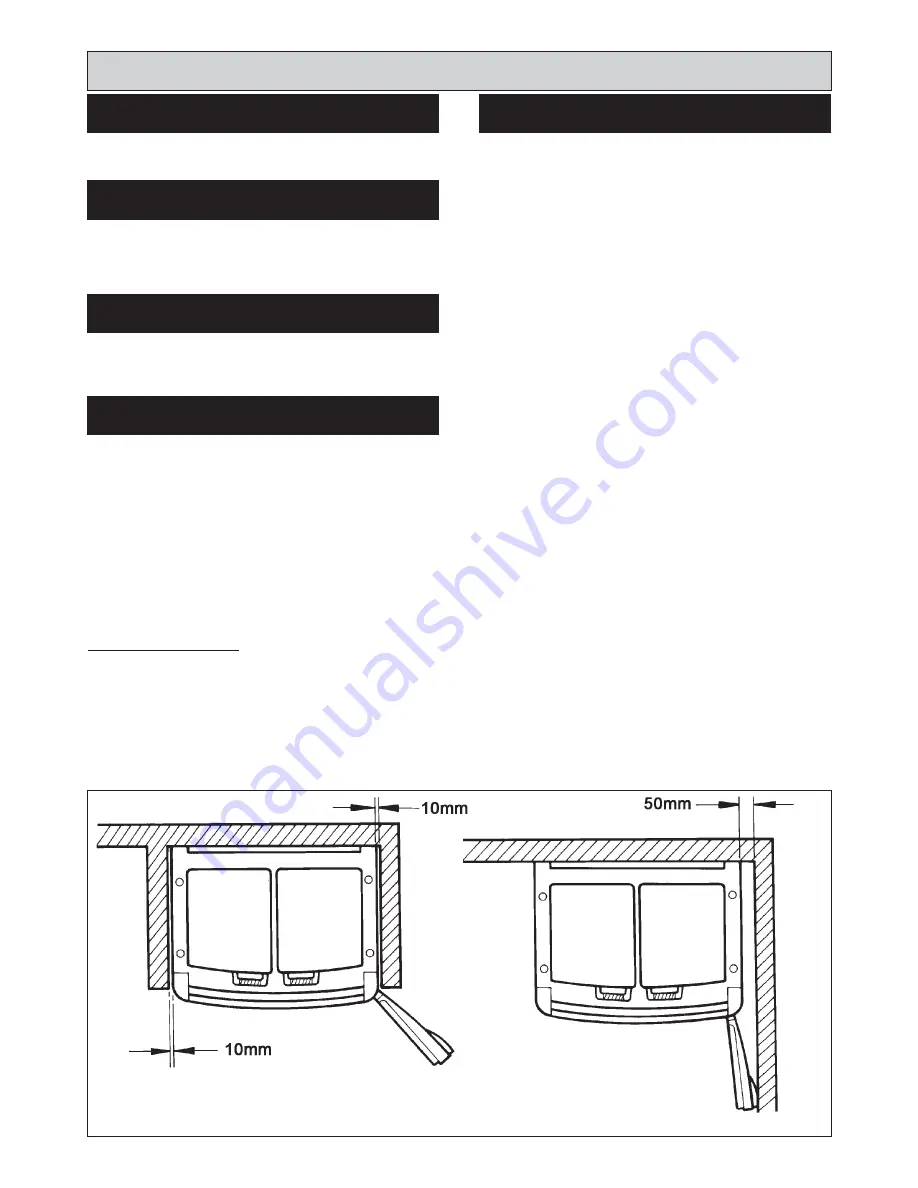

The space in which the appliance is to be fitted must have

the following minimum dimensions.

Between wall or unit and LH side of appliance - 10mm

top plate

Between wall or unit and RH side of appliance - 10mm

top plate

SHOULD THE WALL PROJECT BEYOND THE FRONT

OF THE APPLIANCE, THEN THE GAP AT THE R.H.

SIDE MUST BE INCREASED TO 50mm. TO ALLOW

DOOR TO OPEN ENOUGH TO CHANGE OVEN AND

SHELF POSITIONS, (SEE FIG. 1).

Above the raised insulating cover handle - 60mm

In addition, adequate clearance must be available at the

front of the appliance to enable it to be operated and

serviced. Flue pipes and fittings must not be closer than

10mm to combustible materials and where passing

through a combustible partition such as ceiling or roof,

must be enclosed in a non-combustible sleeve providing

an air space of at least 10mm.

Spaces around flue pipes passing through walls or floors

should be sealed against the passage of smoke and

flame.

Where the cooker is to stand in a recess or against a wall

which is to be tiled, in no circumstances should the tiles

overlap the cooker top plate.

Site requirements

5

IMPORTANT

LOCATION

INTRODUCTION

REGULATIONS

GAS SUPPLY

FIG. 1

DESN 514109

Summary of Contents for XT

Page 20: ...20 Wiring Diagram FIG 21 WIRING DIAGRAM APPLIANCE ...

Page 22: ...22 ...

Page 23: ...23 ...