nVent.com

|

7

2.6 INSTALLATION AND REMOVAL PROCEDURES

2.6.1 Operator Console Installation and Removal

The Operator Console is designed to be easily installed or removed while the Controller is

powered - even in Class I Division 2 and Zone 2 hazardous locations. It may be temporarily or

permanently installed.

The console is installed in three steps:

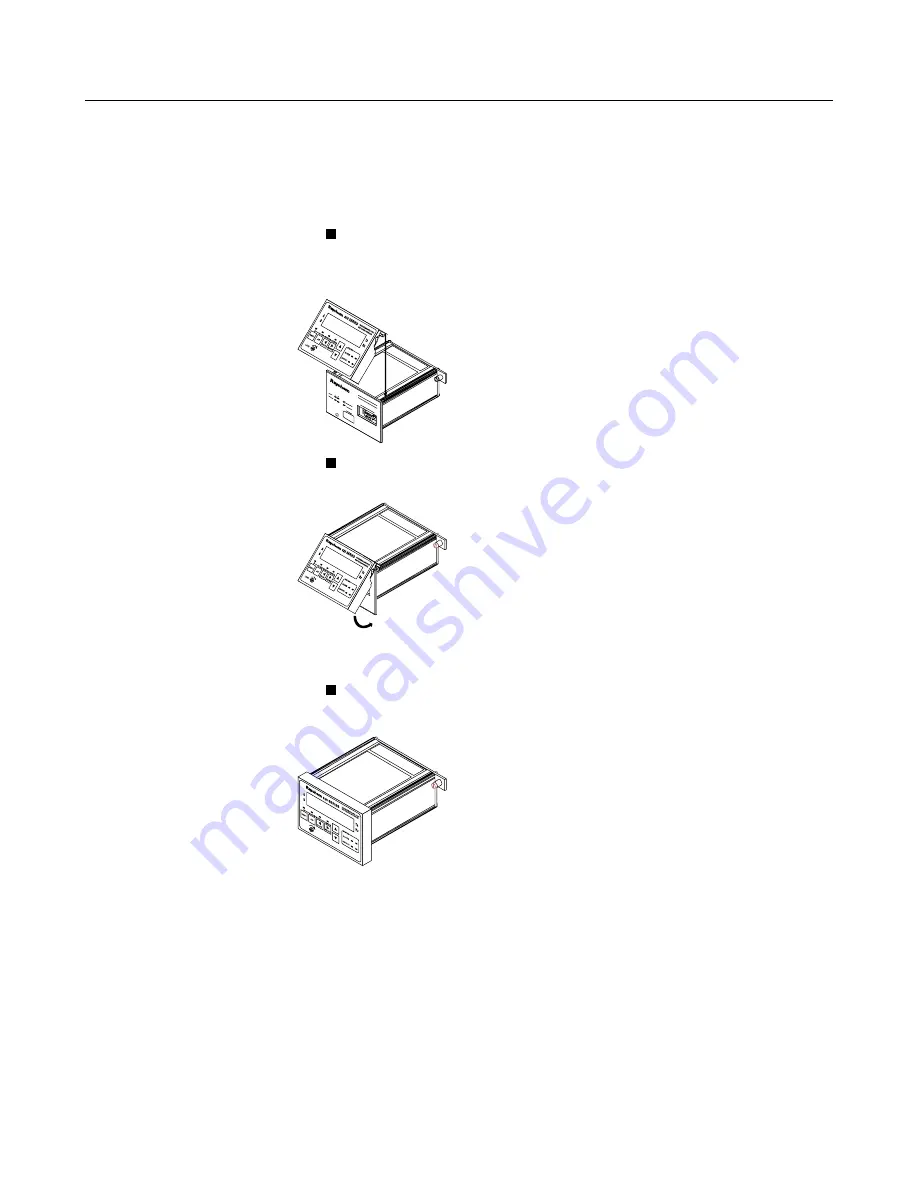

Step

1

“Hook” the lip provided on the rear cover of the Console over the top edge of the

Control Module front plate.

Figure 2.1 Console Installation - Step 1

Step

2

“Hinge” the bottom of the Console downwards until it is flush with the front of the

Control Module.

Figure 2.2 Console Installation - Step 2

Step

3

If the Console is to be permanently installed, secure it to the Control Module using the

captive screw provided. It should be finger tight only. Do not over-tighten the screw or damage

to the console housing may occur.

Figure 2.3 Console Installation - Step 3

To remove the Console, follow the three steps outlined above in reverse order.

Summary of Contents for 920 Series

Page 2: ...2 nVent com ...