4 PRE-INSTALLATION

Cable installations must be preplanned to ensure a

successful installation. It is important to ensure that

personnel are properly trained and qualified for the

specific task they are performing. All applicable rules and

regulations including federal, state / provincial, local, and

municipal laws must be followed. For further information

on installing MI cables, contact nVent Technical Support,

see Section 1.1.

4.1 Minimum Installation Temperature

A minimum installation temperature of −40°F (−40°C) is

recommended for MI cables.

4.2 Precautions

When installing PYROTENAX MI industrial wiring cables,

all appropriate precautions should be followed, including

OSHA and other applicable national safety regulations.

Therefore, in addition to observing standard safety

practices, observe the following:

• Take reasonable precautions to prevent damage to the

cable from severe blows with sharp instruments and

pulling over sharp objects.

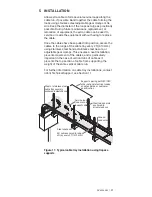

• Do not pull cables around corners that have sharp

edges, such as corners in cable trays, or other

obstructions.

• Pull all cable diameters, one at a time, by hand.

• Hand feed cables around corners using large sweeping

bends.

• When changing direction from horizontal to vertical,

use properly-sized sheaves or pulleys.

• Protect exposed cables from any nearby or overhead

work that could damage the cable.

• Do not pull cables around a radius smaller than the

minimum pulling radius (see Table 2, page 18).

• Make sure all equipment used during cable installation

is in good operating condition.

For further assistance on pulling cables, contact nVent

Technical Support, see Section 1.1.

nVent.com | 11

Summary of Contents for pyrotenax Alloy 825

Page 1: ...MI Cable Industrial Wiring Installation Manual For Alloy 825 Sheath Cables ...

Page 4: ...iv nVent com ...

Page 46: ...42 nVent com ...

Page 47: ...nVent com 43 ...