4 PRE-INSTALLATION

4.5 Set-Up

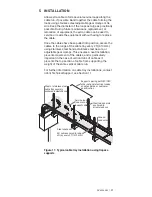

Examine cable trays, trapeze support systems, and other

support systems for acceptability prior to pulling activities.

Install permanent supports properly to ensure the rigidity

of the cable tray, trapeze, or other support system so that

neither the support system nor the cable will be subjected

to damage during the pulling process.

Before installation, verify that the cable(s) can be installed

according to the designed routing and minimum bending

radius requirements.

Where it is not practical to completely remove the cable

from the reel, set up the reel using sheaves or pulleys as

shown in Figure 7 on page 14. The first sheave must be

installed at a point higher than the support system. Use

a roller at the entry and exit points of the tray / trapeze

system. The setup should ensure that the cable is not

kinked or bent beyond the minimum pulling radius (see

Table 2, page 18) or subject to excessive twisting force.

Minimize the amount of tension necessary to pull a cable

as follows:

• Pull in the proper direction. Where practical, a cable pull

should begin nearest the end having the least degrees

of bends and exit the end having the greater degrees

of bends if at all possible. Also, in vertical sections, an

upward pull is preferred.

• Minimize the number and degrees of bends the cable

is pulled around under tension. Accomplish this by

finding the straightest route possible using the least

amount of bends.

nVent.com | 13

Summary of Contents for pyrotenax Alloy 825

Page 1: ...MI Cable Industrial Wiring Installation Manual For Alloy 825 Sheath Cables ...

Page 4: ...iv nVent com ...

Page 46: ...42 nVent com ...

Page 47: ...nVent com 43 ...