In outdoor locations, form a large “U” shaped drip loop

(Figure 17) or a large drip / expansion loop (Figure 18)

at the points of entry into junction boxes and other

equipment. This prevents moisture, which may track along

the cable sheath and collect around the entry point, from

entering the junction box through the hub.

Junction box

Gland connector

MI cable

Drip loop

Figure 17: Drip loop at point of entry into junction box

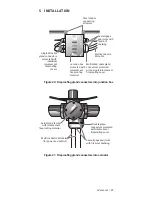

5.3 Installation in Hazardous Areas

Due to the solid construction of MI cable, exploding gases

or vapors and liquids under continuous pressure cannot

travel through it. When terminated with an approved

termination for hazardous areas, MI cable is a proven gas

path block and is used for wiring to equipment and junction

boxes in hazardous areas without the requirement for

conduit and special seals.

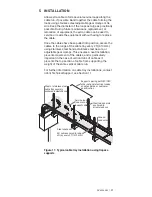

MI cable can be used in place of braided flexible couplings

in areas where limited flexibility is needed. Where the

termination is subjected to vibration, such as when

connecting to a motor, a large expansion loop as shown in

Figure 18 is recommended. In cases of severe differential

vibration, the cable should be terminated into a junction

box adjacent to the vibrating equipment and the final

connection made via a flexible conduit and / or cable.

5 INSTALLATION

26 | nVent.com

Summary of Contents for pyrotenax Alloy 825

Page 1: ...MI Cable Industrial Wiring Installation Manual For Alloy 825 Sheath Cables ...

Page 4: ...iv nVent com ...

Page 46: ...42 nVent com ...

Page 47: ...nVent com 43 ...