8 APPENDIXES

Appendix A: Improving Insulation Resistance (IR)

To maintain the high performance of MI cable, the cable

must be properly stored and the ends must remain sealed.

Damaged terminations or heat shrinkable end caps that are

damaged, missing, or removed will cause the magnesium

oxide insulation (white powder) to absorb moisture,

lowering the IR. The cable must be “heated out” to remove

the moisture and bring the IR back to an acceptable level.

If the IR of a factory terminated cable tests below

acceptable limits (see Section 6), the cable terminations

must be removed before heating out the cable. Follow the

troubleshooting guide in Section 7 before removing the

terminations

Note: Moisture will not normally penetrate more than

12 in (300 mm) into the cable.

If moisture is detected in the cable, use an oxy-acetylene or

mapp gas torch with a large flame and “heat out” the cable

beginning 12 in (300 mm) back from the end. Gradually

stroke toward and past the cable end. Alloy 825 sheath

cables should be heated to a dull red color. Take care not

to overheat any one area of the cable sheath as this could

damage the cable.

Use a short sweeping motion of the torch and heat about

2 in (50 mm) of cable at a time, repeating 4 to 5 times.

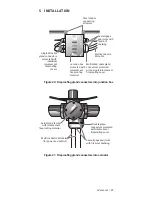

Stroke the flame towards the cable end as shown in

Figure A.1. Do not stroke the flame in the opposite

direction as this will drive the moisture into the cable.

Gradually move the flame toward the end while maintaining

the short sweeping motion of the torch (Figure A.2). If you

heat toward the cable end too quickly you may skip over

the moisture and drive it further back into

the cable.

Repeat the above procedure several times always

beginning 12 in (300 mm) back from the cable end.

38 | nVent.com

Summary of Contents for pyrotenax Alloy 825

Page 1: ...MI Cable Industrial Wiring Installation Manual For Alloy 825 Sheath Cables ...

Page 4: ...iv nVent com ...

Page 46: ...42 nVent com ...

Page 47: ...nVent com 43 ...