Moisture

seal

Moisture

seal

Moisture

seal

Moisture

seal

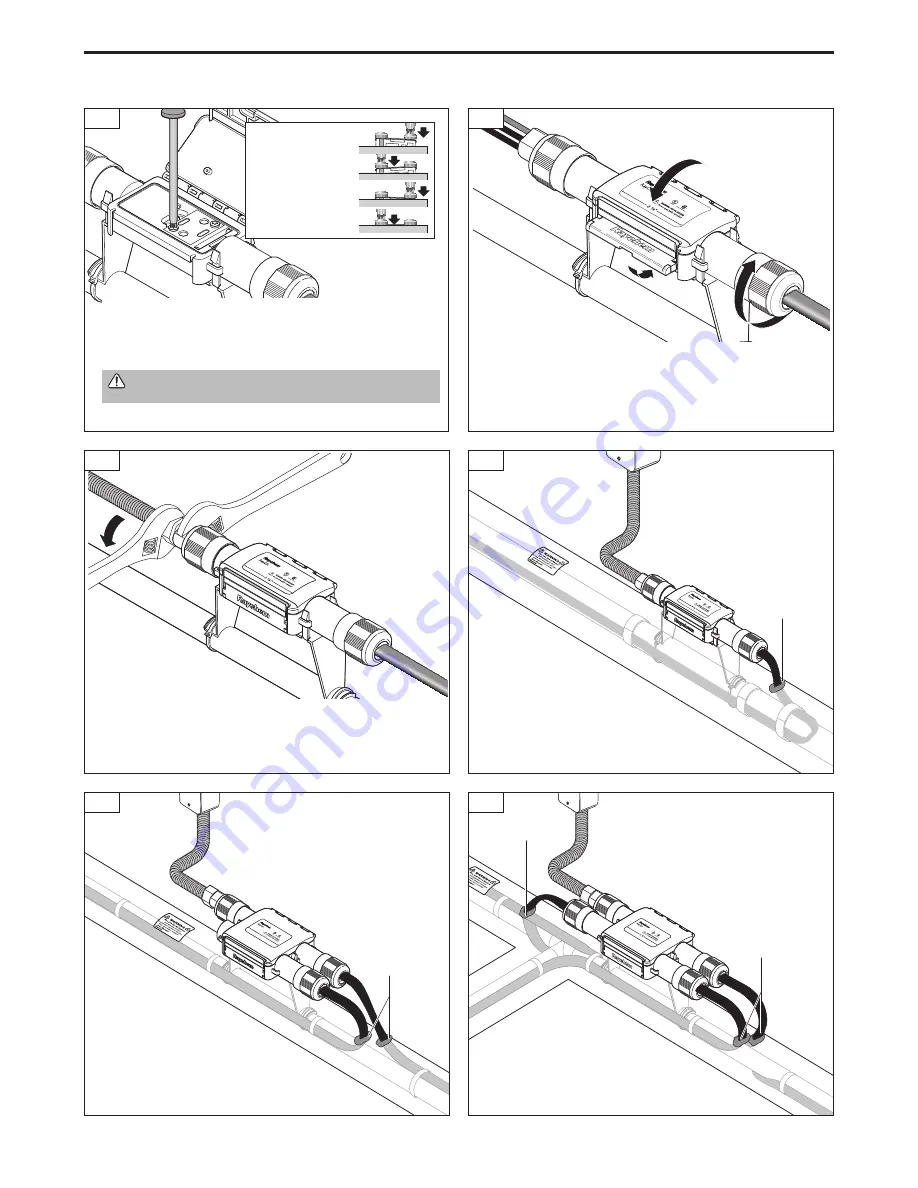

• Using glass cloth tape,

attach heating cable to pipe.

• Apply insulation, cladding and warning labels.

• Terminate power wiring in user-supplied junction box.

• Using glass cloth tape,

attach heating cable to pipe.

• Apply insulation, cladding and warning labels.

• Terminate power wiring in user-supplied junction box.

• Using glass cloth tape,

attach heating cable to pipe.

• Apply insulation, cladding and warning labels.

• Terminate power wiring in user-supplied junction box.

• Using two wrenches, attach user-supplied 1/2-inch conduit.

To avoid breaking housing, do not exceed 15 ft-lbs of torque.

Broken connectors must be replaced.

13B

13C

11

Power Connection

• To prevent damage to heat-

ing cables, protect from

sharp cladding edges.

• To prevent water ingress, seal

the heating cable where it

penetrates the insulation.

Powered Tee

• To prevent damage to heating cables,

protect from sharp cladding edges.

• To prevent water ingress, seal the heating

cable where it penetrates the insulation.

Powered Splice

• To prevent damage to heating cables,

protect from sharp cladding edges.

• To prevent water ingress, seal the heating

cable where it penetrates the insulation.

WARNING:

Fire hazard. Loose screws can cause excessive

heating. Be sure screws are fully tightened.

• Securely tighten the two connection screws, alternating as they are

being tightened.

• For Powered Splice and Tee kits, repeat steps 3 through 8 for all

remaining heating cable entries.

Tighten the screws

until the metal top

surface is at the

same height as the

inner clear plastic

module.

• Close the lid and snap the lever shut. Do not force lid closed; if lid does

not close, check the connection to ensure all screws are fully tightened.

• Tighten the nuts on the heating cable entries until grommets are com-

pressed.

4

RayClic-PC, RayClic-PS, RayClic-PT Installation Instructions

10

13A

12