2 | nVent.com

1. Prepare the sensing cable prior to installation.

FOR TT5000 SENSING CABLE:

Ensure that the end of the cable is sealed with heat-shrink tubing

(as it was when supplied from the factory). If the cable end is not

sealed:

1. Trim the end of the cable as necessary to remove any irregularities.

2. Apply a single layer of masking tape 3/4 inch (19 mm) from the end

of the cable.

3. Push the fluoropolymer braid back and clip it off back to the

masking tape (see illustration at right). Take care not to damage

the black cable jacket; if jacket is damaged, trim the end off and

begin again.

4. Slide one of the heat-shrinkable tubes (catalog no. DWP-125-1/4,

supplied with the bulk reel) over the cable and past the masking

tape. Remove the masking tape, then position the tube so that 3/8

inch (9.5 mm) of the tubing extends beyond the end of the cable.

5. Using a RAYCHEM heat gun or Ultratorch, shrink the tube down to

bond to the sensing cable. Begin at the end over the cable braid.

Apply heat long enough to fully recover the tubing, but not so long

as to melt the braid; do not apply heat directly on the braid, and if

braid is damaged, begin again. In the middle of the tube, continue

heating for 10 to 15 seconds after the tubing has shrunk, to ensure

adhesive in the tubing bonds to the cable jacket. Shrink the entire

tube, finishing at the end off the cable.

6. While the tubing end is still hot, use pliers to crimp and seal the end,

as shown.

7. Let the tubing and cable end cool a minute or two before

proceeding with insertion into the Kellems grip.

3/4 in (19 mm)

Masking tape

Note: Drawings are not to scale

3/8 in (9.5 mm)

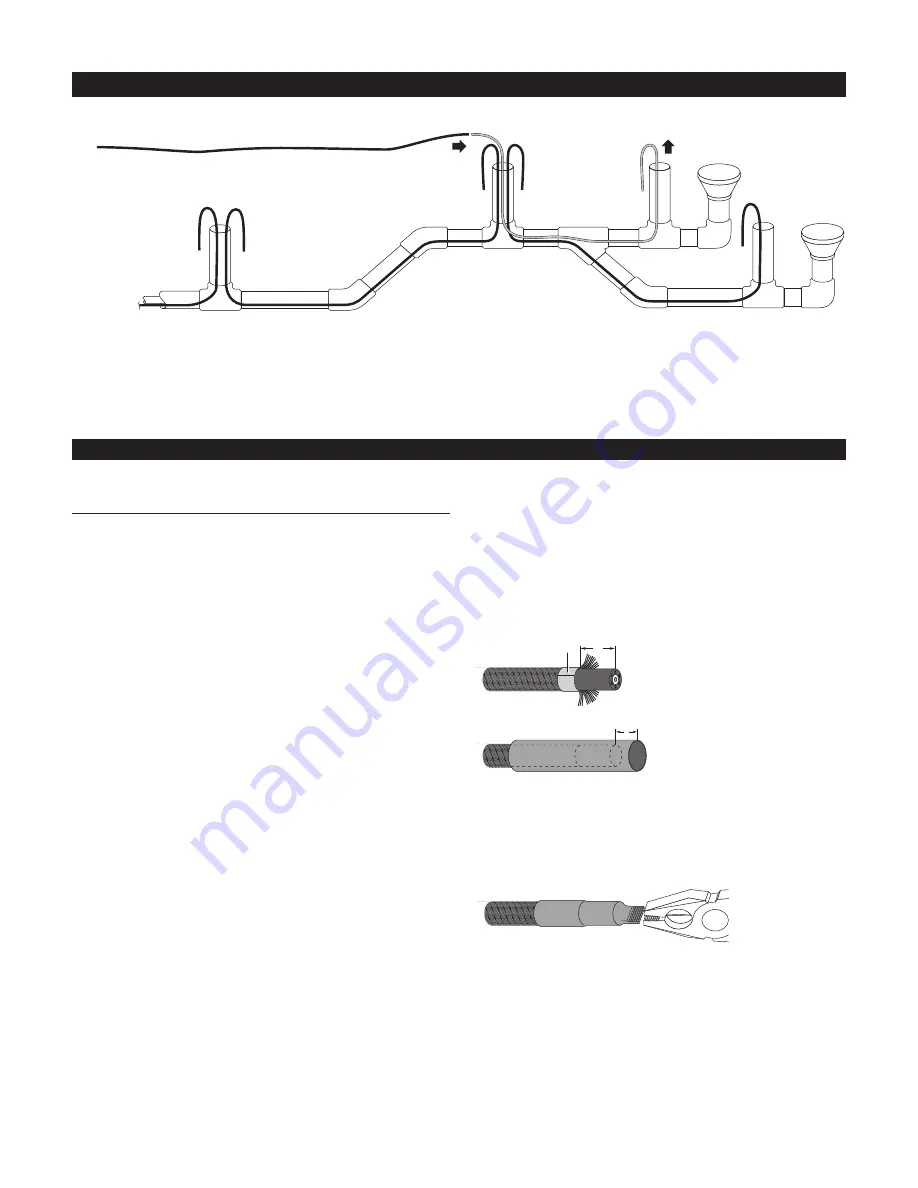

SENSING CABLE INSTALLATION IN DOUBLE-CONTAINMENT PIPING

Installation Steps

Bulk sensing cable

Pull

rope

Check that preinstallation requirements have been met before installing sensing cable in double-containment pipe:

1. The pipe annulus is clean and dry and has been pressure-tested.

2. A continuous length of 1/4-inch to 3/8-inch (6-mm to 9.5-mm)

hollow braid polypropylene or nylon rope has been installed from

access to access of the containment piping as a pull rope.

3. The pull rope moves freely through the pipe (for example, it is

not knotted, pinched, or glued to the pipe).