nVent.com | 5

Tape

SCT

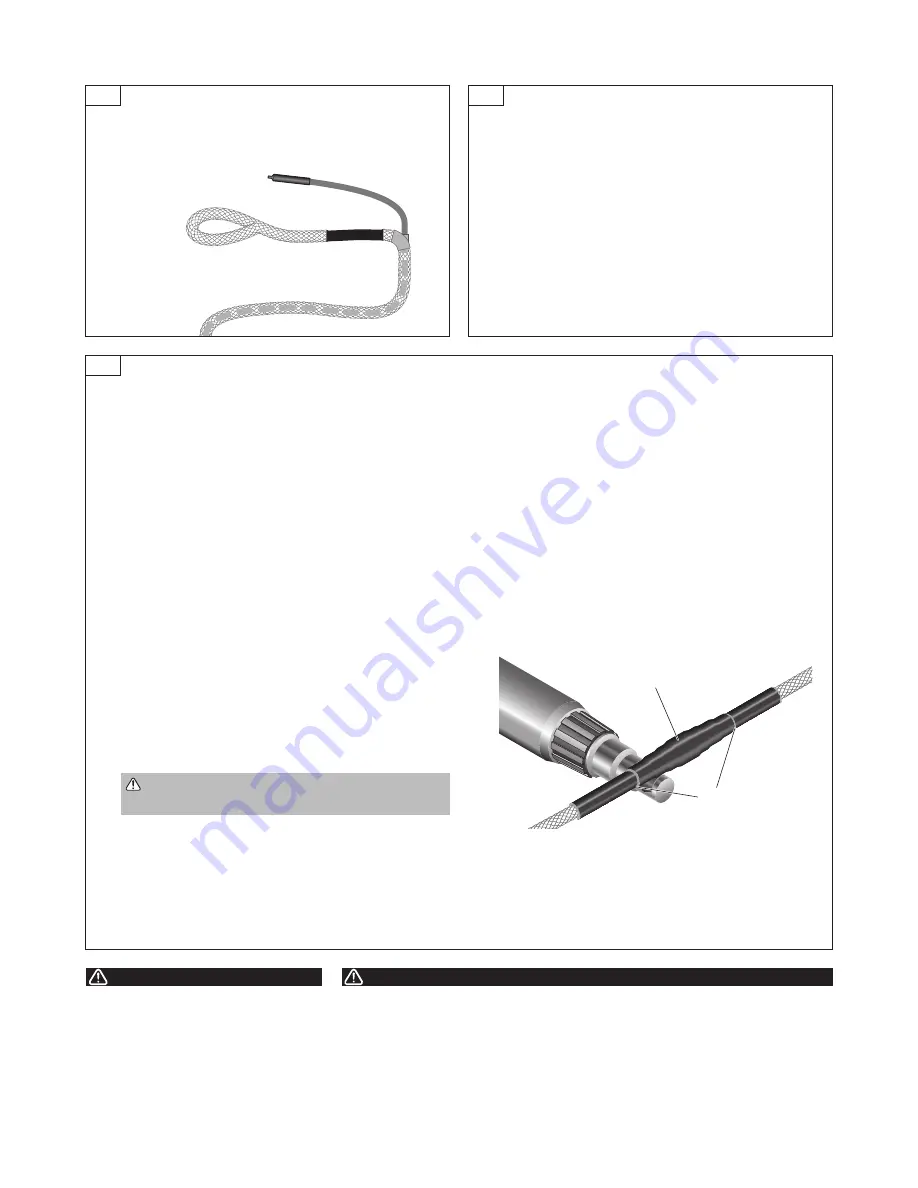

SCT

Unlabeled heat-shrinkable tube

Adhesive visible at

ends of tubing

6

5C

7

Prior to installing a new length of sensor cable, slide the

unlabeled shrink tube (from connector kit) onto the cable.

Connect the sensing cable to the cable circuit (lengths of

sensing cable connected in series) previously installed.

• Mark the connector position on the layout plan.

• Install TraceTek mapping tag (TT-TAG).

•

Note

: As an extra precaution on large installations,

periodically test the entire cable circuit to confirm that all

installed sensing cable is still clean and intact.

• Unplug the end termination and connect it to the next

length of sensing cable to be installed.

Repeat the installation sequence for each length of cable.

• Grasp the sealed end and pull about 12 inches (30 cm) of

sensor cable out while holding the rope braid in place.

• Tape the rope braid to sensor cable to prevent the rope

from springing back.

Complete the system

1. Install other TraceTek components (such as Modular

Branching Connectors, Weighted Lengths, and Modular

Jumper Cables) as called for in the system layout.

Complete the sensing circuit.

Note

: All components of the system have male or female

metal connectors or both. The male connectors are oriented

toward the instrument panel. As new sections of cable are

added to the main leg or branch, each newly added section

should end with an open female connector. The end of each

branch or main leg is terminated with a male end termination.

2. Test the sensing circuit (or portions of it) to confirm that

the sensing cable is clean and intact. Follow the Sensing

Cable Test Procedure.

3. Locate the unlabeled heat shrink tubing segment (delivered

along with the TT500X-HS connectorized cable, or as part

of the TT5000–HUV–CK–MC–M/F connector kit.) Install

the heat shrink tube as environmental seal over all mated

male/female (pin/socket) connections.

• Center the unlabeled shrink tube over the pin/socket

connection. Heat shrink the tube over the connection,

beginning in the center and shrinking towards the ends

until the tube fully conforms to the shape of the connection

and adhesive flows from each end of the tube.

CAUTION: Burn Hazard. Do not get hot adhesive on

your bare skin. The hot adhesive will burn your skin.

• Avoid overheating the thin wall unlabeled shrink tubing.

The thin wall tubing requires less heat than the SCT cable

shrink tubing.

•

Let the entire connector area cool before handling the cable.

Note: Do not leave connector open to environment. If

the connector becomes wet or contaminated, it will need

to be replaced.

Note

: When arranging any TT500X-HS cables do not use a

bend radius less than 2 in. (51 mm).

Note

: If a heat-shrinkable tube must be removed (for

example, for cable testing), refer to Oversleeve Removal

Instructions (H54258).

4. Connect the sensing circuit to the TraceTek alarm module

and activate the system as soon as is practical. Use the

alarm module to monitor for events during the final stages

of construction.

FIRE HAZARD

. Heat guns and flameless heating

tools can cause fire or explosion in hazardous

areas. Be sure there are no flammable materials

or vapors in the area before using these tools.

Follow all site safety guidelines when working in

hazardous areas.

Component approvals and performance are based

on the use of specified parts only.

HEALTH HAZARD

. Overheating heat-shrinkable

tubing will produce fumes that may cause

irritation. Use adequate ventilation and avoid

charring or burning. Consult MSDS RAY3122 for

further information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258

.

WARNING:

CAUTION: