nVent.com | 7

Sensing Cable Test Procedure

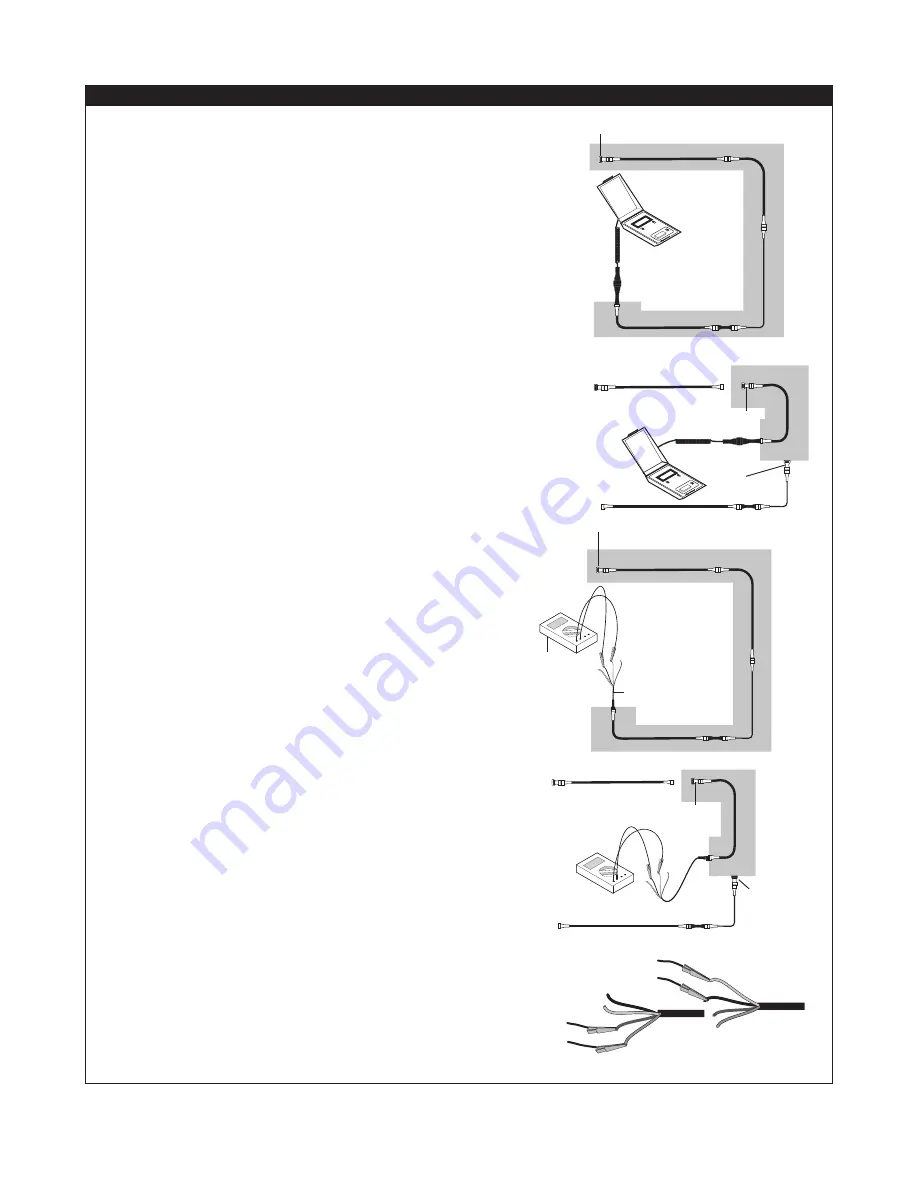

Method with nVent RAYCHEM TraceTek Portable Test Box

(TT-PTB-1000)

1. Ensure the end termination is connected to the sensing cable.

If checking several lengths of sensing cable in series (a cable

string), ensure they are all connected.

2. Connect the PTB to the sensing cable(s) using its

adapter, as illustrated.

3.

Verify that the sensing cable is intact;

follow the operating

instructions printed inside the lid of the PTB itself. If a cable

or connection is broken, the PTB illuminates its LED indicating

“cable break,” and displays a “1” in the leftmost position of its

LCD display. If the cable string is intact, the PTB measures the

system length.

• If the cable string is not intact, apply this test procedure to

segments of the system to identify the open connection or

damaged modular length.

•

Note

: If a heat-shrink tube must be removed to

access a connector, refer to Oversleeve Removal

Instructions (H54258).

4.

Check the condition of the sensing cable(s),

again following

the PTB operating instructions. If the sensing cables are clean

and free of contamination, the current measured should be

0 µA. If the reading exceeds 10 µA, use the PTB to locate the

liquid or contamination and take appropriate corrective action.

Method with Ohmmeter

1. Ensure the end termination is connected to the sensing cable.

If checking several lengths of sensing cable in series (a cable

string), ensure they are all connected.

2. Connect a Modular Leader Cable (TT-MLC-MC) to the

sensing cable.

3.

Verify that the sensing cable is intact:

• Loop 1: Measure the resistance between the yellow and black

wires of the leader cable as illustrated.

• Loop 2: Measure the resistance between the red and green

wires of the leader cable.

The readings should roughly equal a multiple of the length of

sensing cable:

4.0 times the length of sensing cable (in feet), or 13.1 times

the length of sensing cable (in meters).

Example:

4.0 x 50 ft of cable = 200 Ω

13.1 x 15 m of cable = 197 Ω

In addition, the resistance of the two loops should be within

5 percent of each other.

If the cable string is not intact, apply this test procedure

to individual segments of the system to identify the open

connection or damaged modular length.

Note

: If a heat-shrink tube must be removed to access a

connector, refer to Oversleeve Removal Instructions (H54258).

4.

Check the condition of the sensing cable

. Measure the

resistance between the black and green wires of the

leader cable.

If the reading is below 20 megohms, apply this test procedure

to individual segments of the system to identify the modular

sensing cable length(s) affected, locate the damage or

contamination, and take appropriate corrective action.

End termination

End termination

Testing an

individual

length of

cable

Testing a

cable string

End

termination

PTB

TRACE

TEK

TRACE

TEK

Testing an

individual

length of

cable

Testing a

cable string

End

termination

TT-MLC-MC

Ohm

meter

End termination

End termination

To yellow

To black

To red

To green