8 | nVent.com

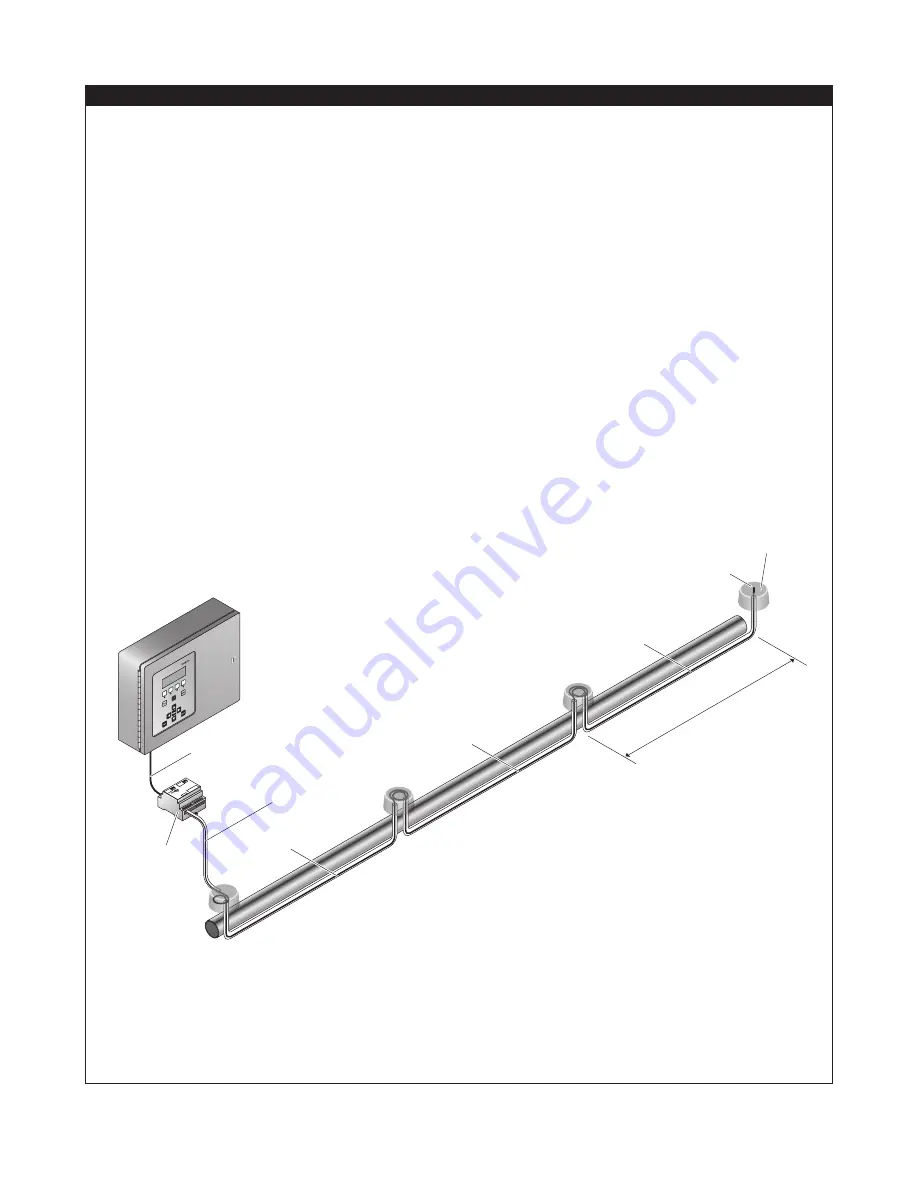

Complete System Connections and Layout

A. TT500X-HS is available in bulkform, cut to length in the field

and joined using connector kits–or it can be obtained in

standard or custom cut lengths with connectors attached in

the factory. Each cable has a female metal connector on one

end and a male metal connector on the opposite end. Cable

sections plug together like extension cords.

B. (Optional) A branch connector (TT-MBC-MC-TW) is used

to connect and branch “T” lines. The branch connector

has one male connector and two female connectors. For

mapping purposes, the cable connected to the center leg of

the branch connector will be counted first, then the distance

measurements will continue from the second female

connector and continue along the rest of the system. A dead

band of 16 ft (5 m) is inserted at the beginning of each branch

to avoid any location ambiguity.

C. (Optional) It is permissible to have multiple sub-branches as

needed to fully trace the pipe system.

D. Install an end termination (TT-MET-MC) at the end of the main

line and each branch line. (Note: A good check on the system

design and bill of materials is that the total number of end

terminations installed in the system should equal the number

of branch connectors plus one).

E. (Optional) Install jumper cables (TT-MJC-xx-MC-BLK) as

needed if they are to connect sensing cable sections in

separate areas. Jumper cable is available in various pre-cut

and terminated lengths and is also available in bulk form

for long distance runs between the sensor cable and alarm

module location.

F. Install a leader cable (TT-MLC-MC-BLK) between the sensor

cable and the alarm module location. The factory standard

length of leader cable is 12 ft (4 m). It has a female metal

connector on one end and four tinned leads on the opposite

end for connection at the alarm module terminal block. In

some installations the distance between the alarm module

and the start of the sensor cable run will be much greater

than 12 feet. In those cases a simple solution is to purchase

a jumper cable of sufficient length, then cut off and discard

the male connector and any extra cable. Bulk jumper cable

and splicing kits are also available for lengths that exceed the

longest available standard jumper cable.

G. Use fastening straps to neatly coil and secure any excess

sensor cable, jumper cable, branch connectors, etc.

Modular jumper cable

(TT-MJC-xx-MC-BLK)

in conduit

RS-485 twisted pair

Note:

• Drawing not to scale.

• Not shown: heat-shrinkable tube

to cover each connection.

TraceTek alarm module

(several models available;

TTDM-128 alarm and

locating module is shown)

CH2

3 CGN

SUN

12 0

4 08

ACA

C

SHLD

RS–

RS+

AC AC

SHLD

RS–

RS+

AC AC

RED

GRN

YEL

BLK GND

TTSIM-1

Leak Location Module

RATING: 24V

ac

±

10%

50/60 Hz

3VA

Network

Addr

ess

8910

11

12

8910

11

12

TTSIM-1

(Sensor

interface

module)

TT500X-HS

in slotted pipe

240 m Max.

Do not exceed 240 m Max.

between pull boxes

TT500X-HS

in slotted pipe

TT500X-HS

in slotted pipe

Modular end termination

(TT-MET-MC)

Pull Box

TRA

CETE

K