Copyright © 2000 Rayco - All Rights Reserved

Printed in U.S.A.

RG 1635A STUMP CUTTER

RAYCO

®

26

O

PERATION

NOTICE

Clean hydraulic oil is essential for the proper

function of the hydraulic components. The oil

and filter should be changed in accordance with

instructions contained in the •Maintenance

Intervals• section of this manual, or sooner if the

hydraulic system becomes sluggish.

If the fluid smells burnt or the natural color of the

fluid has become black or milky, it is possible that

an overheating or water contaminant problem

exists. The problem should be corrected, and the

hydraulic oil changed, before continuing use of

machine.

Use only clean, fresh hydraulic oil, free of

bubbles. (Bubbles indicate trapped air.)

Lubricating Grease

All

RAYCO

®

stump cutters are completely serviced at

the factory before shipping. The operator should

check all grease fittings to familiarize himself with

their location and acquaint himself with the correct

service schedule.

WARNING

Use the normal shutdown procedure (See

•Operating Instructions•), before lubricating

the machine.

Use only a high quality, multipurpose grease which

contains 3% to 5% molybdenum disulfide. Use NLGI

NO. 2 (or NO. 0 grade for extremely low

temperatures). Before lubricating make sure all grease

fittings and the nozzle of the grease gun is clean.

Fluids Refill Capacities

(Approximate)

Drive Belts

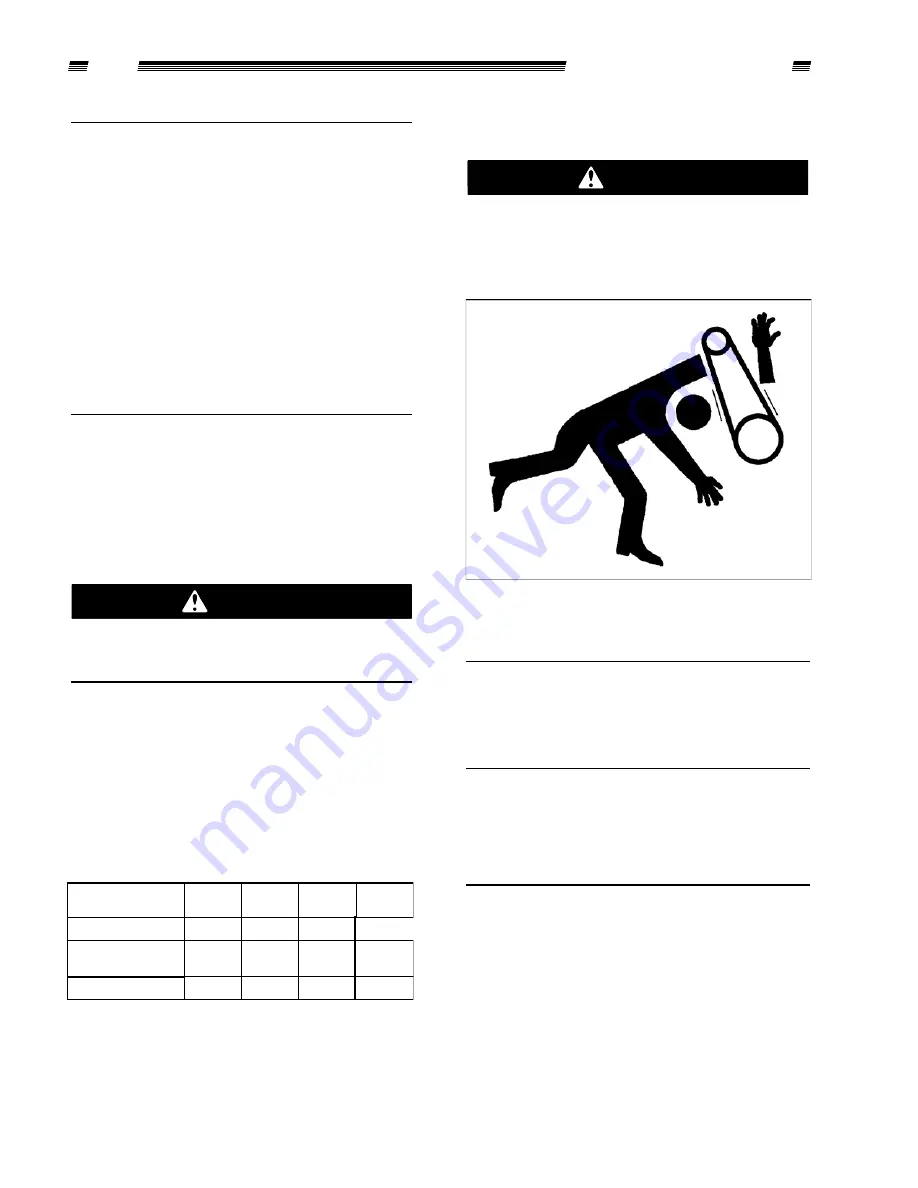

WARNING

Before beginning to check or adjust belt:

shutdown the machine, ensure that all moving

parts have come to a halt, remove the key from

the engine start switch, and place the key in

safekeeping.

Extreme caution must be used to avoid death

or serious injury. Stay clear of belts and

chains and cutting wheel when they are

moving!

The cutting wheel is driven by the engine via v-belts ,

a jackshaft and a Poly Chain GT belt.

The hydraulic pump is driven through connection to

the engine shaft via a v-belt.

NOTICE

To extend belt life proper tension must be

maintained. A loose belt will cause excessive

cutting wheel slippage and belt failure. A belt

that is too tight can cause bearing, shaft and

belt failure.

Compartment or

System

Quarts

U.S.

Gallons

Imperial

Gallons

Liters

Fuel Tank

NA

14.00

11.66

53.00

Engine Crankcase

(Including oil filter)

4.00

1.00

0.83

3.74

Hydraulic System

7

1.70

1.42

6.40