RG55R Operation • Service • Maintenance

18

Safety

condition.

3. Remove all non essential items.

4. Inform all affected personnel.

5. Check to see that all affected persons are located in

a safe position.

6. Inform the worker of the lockout/tag out removal

before the worker starts to work for his/her next shift.

7. When more than one person works on the same

equipment, multiple lock/tag outs must be used. Only

when all locks are removed can the equipment be

energized.

Removal Procedure

• Lockout/tag out equipment must be removed by the

worker who placed it.

Parking

Park on a level surface. If you must park on a grade, chock

the machine.

1. Move the joystick control slowly to the NEUTRAL position

in order to stop the machine.

2. Move the throttle control lever to the LOW IDLE position.

3. Lower all implements (if equipped) so that the work tool

implement rests firmly on the ground.

4. Move the hydraulic controls to the NEUTRAL position.

5. Turn the engine start switch key to OFF position and

remove the key.

6. Disconnect the operator restraint devices (if equipped)

and exit the machine.

While Servicing and Performing

Maintenance on the Machine

• ALWAYS Block the wheels to prevent unintended

movement.

• Adhere to your LOCK-OUT/TAG-OUT procedure when

performing maintenance or repairs to this machine.

Locking and tagging out equipment safeguards

those working on equipment from being injured by its

unexpected energized or releasing stored energy.

• To prevent fires, clean debris and chaff from the engine

and muffler areas.

• Periodically check that all nuts and bolts, hose clamps,

and hydraulic fittings are tight.

• When removing the fuel cap, unscrew it slowly, and

hold it firmly. The cap may otherwise be thrown due to

pressure buildup caused by an increase in temperature.

• For your safety, repair or replace all damaged or worn

parts immediately. Replacement parts which are

authorized by Rayco are the only parts which should be

used for repair or replacement on this machine.

• Altering this equipment, or using this equipment in

such a way as to circumvent its design capabilities and

capacities, could result in serious injury or fatality and

WILL VOID THE WARRANTY.

• Do not alter this machine in any manner. Alterations

such as attaching a rope to the control bar may result

in personal injury or death.

• NEVER remove the cap from the hydraulic tank or

reservoir while the machine is running. Hot oil under

pressure will cause injury.

• Relieve hydraulic system pressure before repairing

or adjusting fittings, hoses, tubing, or other system

components.

Pre-Transportation Checks

• Never allow inexperienced drivers to tow the machine.

• When towing, always make sure the tow vehicle ball

hitch and trailer/machine hitch coupler are the correct

matching size and style.

• Always make sure the tow vehicle and the trailer/machine

are on level ground and the wheels are chocked before

connecting or disconnecting.

• Make sure the tow vehicle is of adequate size and has

the towing capacity to safely tow the combined weight

of trailer/machine.

• Never tow a machine while it is running.

• Towing will affect handling, allow for extra stopping

distances. Refer to U-Haul’s “Safe Trailering” Driver

Education Program that is available at this website: http://

www.uhaul.com/guide/index.aspx?equipment=towing-

autotransport

• Make sure the towing eye is at the proper height so the

machine tows level when traveling. A proper amount of

tongue weight is required to allow the machine to tow

properly. Too little tongue weight will result in wandering,

fish-tailing, and/or axle damage.

NOTE: Use caution when backing up. The rear of the machine

may not be visible from the towing vehicle. It is recommended

to use a spotter outside the vehicle.

• Be aware of the length of the EQUIPMENT while

turning, parking, crossing intersections, and in all driving

situations. When arriving at the work site, do not set

up the EQUIPMENT under a tree that is being pruned,

cut, or worked on.

Important Towing Information

PREVENT WHIPPING by properly loading the auto transport

trailer. Load the heaviest end (engine end) of the vehicle-in-tow

to the FRONT of the trailer. Loading heavier in the rear can

cause the tow vehicle and transport trailer “combination” to

begin WHIPPING, which is violent and uncontrollable sway.

SIDE to SIDE MOTION (SWAY) THAT BEGINS as you

reach a certain speed, will likely become WHIPPING at

higher speeds. If you notice sway beginning SLOW DOWN

IMMEDIATELY by letting off the gas pedal. Then stop to

reload the vehicle-in-tow heaviest end forward as soon as

possible, and remove any cargo from the vehicle-in-tow

Summary of Contents for RG55

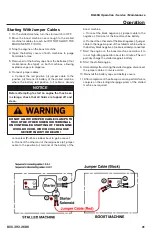

Page 27: ...RG55R Operation Service Maintenance 800 392 2686 27 Operation ...

Page 58: ...RG55R Operation Service Maintenance 58 Hydraulic Schematic 805921 ...

Page 59: ...RG55R Operation Service Maintenance 800 392 2686 59 Hydraulic Schematic 805921 ...

Page 67: ...RG55R Operation Service Maintenance 800 392 2686 67 Specifications ...