RG55R Operation • Service • Maintenance

800.392.2686

45

Maintenance

remove a clear “kerf” from the stump without the body

of the tooth ever contacting the stump. This concept

reduces drag, which maximizes the use of the machine’s

horsepower. This also reduces wear on the tooth body

and on the attachment hardware. Many of the other

cutting tool systems available today do not address this

important aspect of cutting.

• Cutting Tool Dimensions: Rayco’s stump cutting teeth

are carefully designed to have the proper size of carbide

tip. Carbide tips ultimately become dull, and using

large, oversized carbide tips will induce extreme impact

energies into the machine’s structure.

• Debris Retention: Rayco’s cutting tool patterns are

designed to minimize the retention of debris in between

the cutting tools. This debris can cause imbalance. This

debris can also become a dangerous projectile. Non-

Rayco cutting tools may retain more debris.

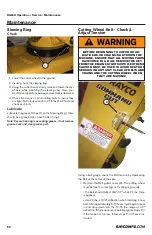

Changing Teeth

Remove the socket head bolts from the teeth. (Use the 1/2”

hex key provided with the machine.)

• Clean all dirt from the cutting wheel and teeth.

• Check the cutting wheel for cracks. Re place the wheel

if it is cracked.

• Carefully select and insert new cutting teeth, properly

positioning each tooth as shown in the diagram on the

next page.

• Bolt the teeth to the cutting wheel (but not tightly until

the pattern has been double-checked).

• After setting each tooth pair, tighten the socket head

bolts to 135 to 145 foot-pounds.

Replacement teeth are available from your Rayco dealer or

direct from Rayco. Refer to the Parts manual for part numbers

The Cutter Wheel (1) Rayco part# 35244 on the RG55 uses

6 different types of SuperTeeth as shown below:

2)Straight Tooth - Part# 3144T (threaded) Qty of 3

3)Angle-Out Tooth - Part# 2933T (threaded) Qty of 9.

4)Straight Tooth - Part# 3144C (countersunk) Qty of 3.

5)Angle-Out Tooth - Part# 2933C (countersunk) Qty of 9

BLOCK OR OTHERWISE SECURELY SUPPORT

THE CUTTING BOOM WHEN CHANGING

TEETH.

NOTICE

Read all of the following instructions before

beginning to change the cutting teeth.

NOTICE

The following illustrations represents the exact

location required for positioning each tooth. Please

follow the diagrams very closely for good cutting

wheel performance.

2

3

3

3

2

3

3

3

3

3

3

2

1

1

4

5

5

5

4

5

5

5

4

5

5

5

NOTICE

DO NOT hammer the tip of a tooth. Due to the

super hardness of the tooth, it is brittle and may

chip from such treatment.

Summary of Contents for RG55

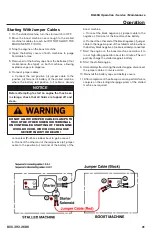

Page 27: ...RG55R Operation Service Maintenance 800 392 2686 27 Operation ...

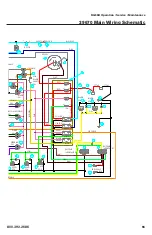

Page 58: ...RG55R Operation Service Maintenance 58 Hydraulic Schematic 805921 ...

Page 59: ...RG55R Operation Service Maintenance 800 392 2686 59 Hydraulic Schematic 805921 ...

Page 67: ...RG55R Operation Service Maintenance 800 392 2686 67 Specifications ...