T415 Operation & Service Manual

52

Maintenance

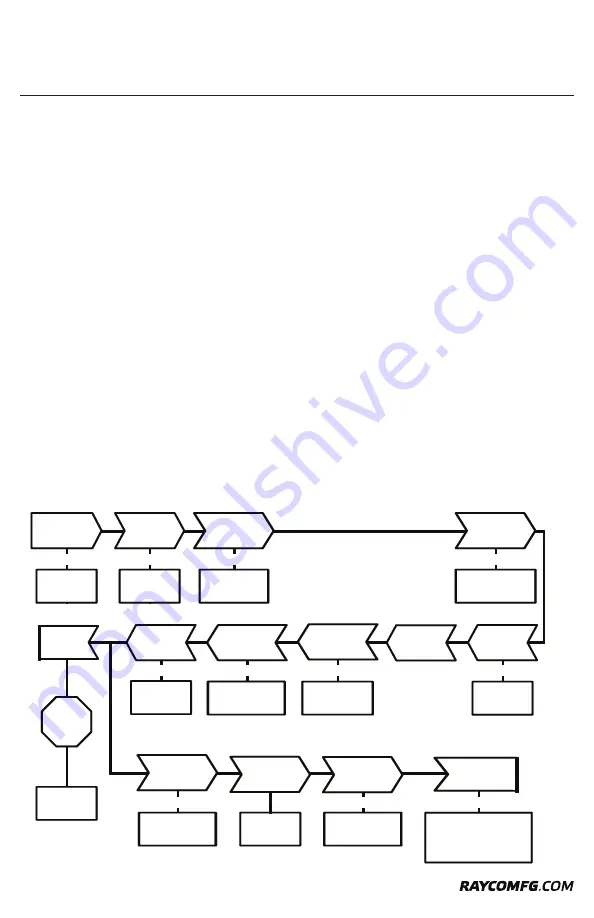

CHECK

ALL

FITTINGS

FILL

RESERVOIR

SUPPLY 10 PSI

MAXIMUM

COMPRESSED

AIR

LOOSEN CASE

DRAIN OUTLET

AT MOTOR

BE

TIGHT

PROPER

FILTERED

FLUID

SEALED

RESERVOIR

MUST

IF

NOT

STOP

AND

TROUBLE

SHOOT

WITH

TO

FLUID TO FILL

BOTH PUMP AND

MOTOR CASES

ALLOW

CHARGE

PRESSURE

OR

RUN

PRIME

MOVER

CONTROL

IN

NEUTRAL

WHEN

FLUID

AT LEAST

200 TO

220 PSI

CHARGE PRESSURE

GAUGE

STARTS CLIMBING

40 SECONDS

AT

LOW SPEED

TIGHTEN CASE

DRAIN OUTLET

AT MOTOR

IS

UNTIL

FOR

APPEARS

SET

PRIMER

MOVER

CYCLE PUMP

CONTROL

SLOWLY

CHARGE

PRESSURE

STOP

PRIMER

MOVER

50% OF

MAXIMUM

THROTTLE

2 OR 3

TIMES

DROP APPROX.

40 PSI

IN CHARGE

REMOVE GAUGE

REPLACE PLUG

CHECK FLUID LEVEL

SYSTEM READY TO

OPERATE

AT

SHOULD

THEN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

and motor cases to fill with fluid for instant lubrication

at start-up.

5. Fill Pump and Motor Cases of the circuit through the

uppermost case drain ports. This gives both units

instant lubrication at start-up. Also remove top hose

connection of the HC (Hydraulic Cylinders) pump, fill

with oil, and reinstall top hose connection. This will

provide instant lubrication to HC pump at start-up.

6. Placing the pump Control in Neutral at start-up

is essential to prevent any unexpected machine

movement.

7. Run the Prime Mover (engine) for a short period

of time using the starter. (Crank the engine briefly,

repeatedly.) This allows the charge pump to start

filling the system. Start the engine and run at lowest

speed. Shut the engine down within 40 seconds if

the charge pressure does not increase steadily to

approximately 340 to 440 Psi.

8. Or run the prime mover until the charge pressure

gauge starts climbing steadily, showing the system is

filling. If the charge pressure gauge does not move,

stop the prime mover and recheck installation.

9. Charge Pressure should be steady at approximately

340 to 440 Psi. This indicates the system is full.

10. If Not at this pressure, stop the prime mover and

troubleshoot the installation and system.

11. Set the Prime Mover at approximately 50 percent of

maximum throttle for a few minutes. This will purge

any remaining trapped air from the system.

12. Cycle Track Control Slowly. Restart the prime mover,

and actuate the track control two or three times to

purge any trapped air from the system.

13. Stop the Prime Mover and remove pressure gauge

used at start-up. Replace the plug. Recheck the

reservoir fluid level and add fluid if necessary. Replace

the reservoir cap.

The hydrostatic circuit is now ready for operation.

Hydraulic Circuit

After the hydrostatic circuit is ready, the hydraulic circuit

may be prepared.

1. Check the reservoir level, and add more clean fluid if

necessary. Fill all other components in the HC circuit

with hydraulic oil as completely as possible.

2. Start the engine and run it at normal operating speed.

Using the boom motion controls, slowly, then at

normal operating speed, cycle the boom through all

its motions until all air is bled off. The motions will be

smooth and powerful when all of the air is bled off.

3. Check the reservoir level, and add more clean fluid if

necessary.

4. Remove the reservoir fill neck, and inspect strainer,

cap, and gaskets. Replace if damaged or worn. Clean

the strainer in clean, non flam ma ble solvent, and dry.

Install the strainer. Put a light coat of fuel oil on the fill

neck gasket. Install the fill neck. Inspect the gasket on

the breather cap, and replace if damaged. Install the

breather cap.

5. Clean up any spilled hydraulic fluid.