Fig.6

DISHED WHEEL

METAL WHEELS

To attach the drive unit to the wheel:

l

Place the drive unit with the clamping

face uppermost i.e. drive motor and

gearbox tube downwards.

Position one spacer at each of the

three attachment positions (if the

wheel is dished).

Remove

and place it on top

of the drive unit making sure the face

which is nearest the pedestal is

downwards.

l

Place the clamps over the spokes and

lightly tighten the bolts supplied

(Fig. 7).

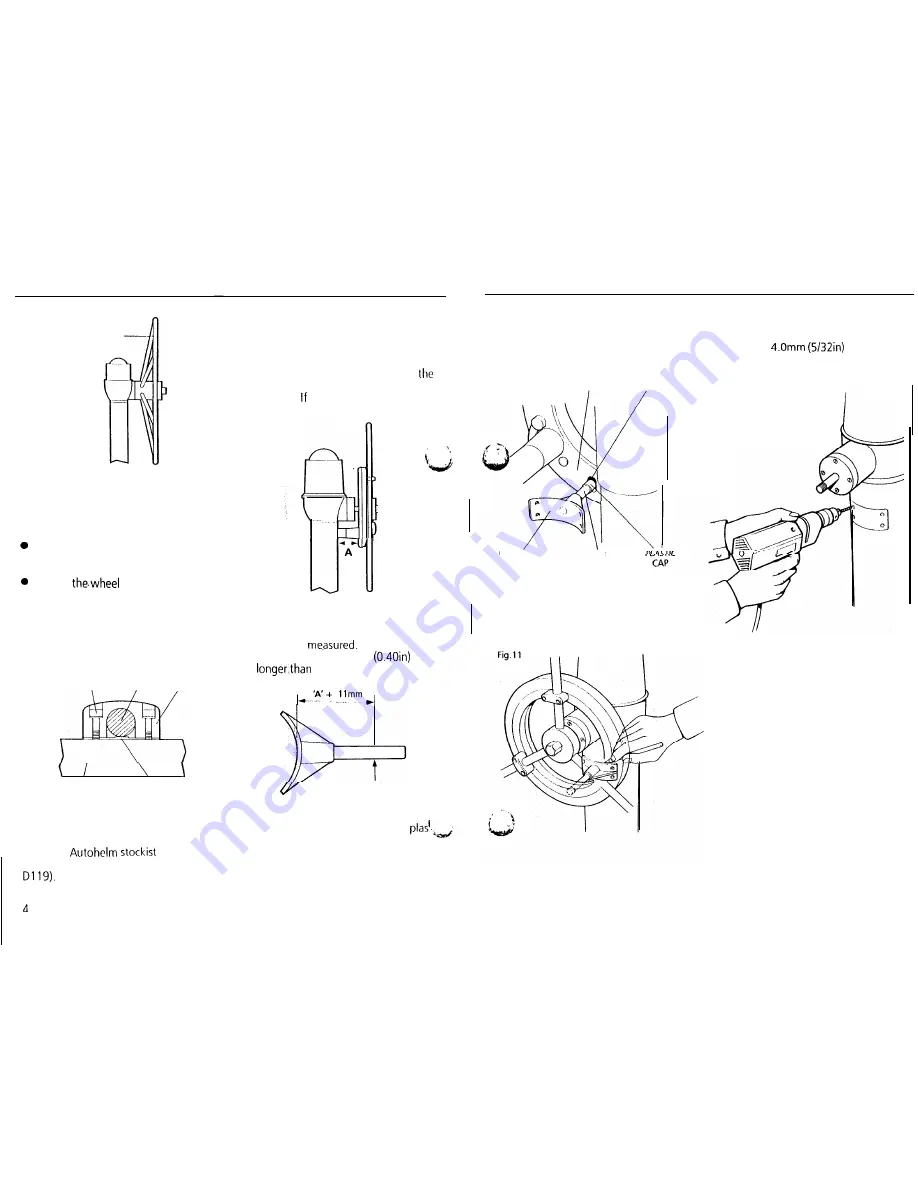

Fig.7

FIXING BOLT

S P O K E

CLAMP

DRIVE UNIT

SPACER (IF REQUIRED)

WOODEN WHEELS

A separate attachment kit is available

from your

for use with

wooden wheels (Catalogue number

MOUNTING THE PEDESTAL BRACKET

The pedestal bracket pin should be cut to

length to suit the pedestal as follows:

l

Replace the wheel and measure the

distance between the backplatc of

drive unit and the pedestal (dimension

A

Fig. 8). the wheel is slightly bent,

Fig.8

3

the distance will change with the

wheel position. The smallest distance

should! be

The mounting

pin should be cut 11 mm

dimension

A

(Fig. 9).

Fig.9

CUT HERE

Remove any burrs and place the

cap supplied over the cut end.

l

Slide the wheel forward and place the

pin end with the plastic cap in the slot

(Fig. 10)

l

Remove the wheel and mark round the

inside of the four holes.

Fig.10

DRIVE UNIT

BACK PLATE

S L O T

l

Drill four

diameter

holes with the drill bit supplied

(Fig. 12).

Fig.12

PEDESTAL

BRACKET

P I N

l

Return the wheel to its normal position

and with the pin mid-way in the slot,

carefully mark round the bracket to

record its position (Fig. 1 1).

l

Attach the bracket and lightly tighten

the screws.

l

Replace the wheel making sure the pin

locates in the bracket. Turn the wheel

to confirm the bracket is correctly

positioned. If the wheel is slightly bent,

or the wheel drive slightly off centre,

the pin will move up and down in the

slot of the backplate. Provided the pin

does not reach the end of the slot this

movement is acceptable.

l

Fully tighten all four screws.

Summary of Contents for Autohelm 4000

Page 2: ......