3.4 Mounting

Transducer assembly

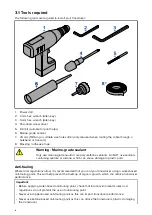

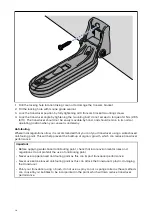

Follow the steps below to assemble the transducer ready for attaching to the Transom bracket.

1. Slide the hanger bracket over the top of the transducer until the notch in the side of the bracket

hanger aligns with the unlocked symbol on the side of the transducer.

2. Allow the hanger bracket to move down into the slots on the top of the transducer.

3. Slide the hanger bracket in the opposite direction from step 1, so that the notch in the side of the

bracket hanger aligns with the locked symbol on the side of the transducer.

4. Secure the hanger bracket to the transducer, using a 4 mm Hex wrench (Allen key) and the

supplied M5 hex bolt and washer.

24