Installation

12

6.

If the hull of the boat has a core-type hull, you will need to follow

some special mounting procedures. The core material must be

protected from any water which may leak from the inside of the boat.

(If the core material is allowed to remain wet, it may rot and weaken

the hull.)

7.

When working with the transducer, support it by holding the body of

the unit or the rings. Do not hang the transducer from the cable.

8.

It is very important to seal the opening around the transducer using a

high-quality marine sealant suitable for underwater use. After

installation, do not leave your boat in the water for any amount of time

without checking for leaks.

Installation Notes – In-Hull Transducer

Detailed instructions for this installation will be included with the trans-

ducer. In this section, we will note just a few important points.

1.

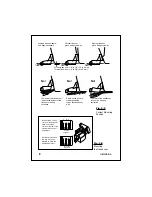

Choose the best mounting location:

For outboard powerboats – Install as far aft as possible

For inboard/outboard powerboats – Install close to the engine(s)

For inboard powerboats – Install forward of the propeller(s) and

shaft(s)

For sailboats – Install near the centerline of the hull and forward of

the leading edge of the keel

2.

An in-hull transducer may only be installed in a fiberglass hull which

is no more than 1" (25 mm) thick. The in-hull transducer may not be

installed in wood or aluminum hulls.

3.

Use the standard in-hull transducer if it will be installed in a flat part

of the hull, or a section with no more than 10° of deadrise. Use the

angled in-hull transducer if the mounting location has up to a 22° of

deadrise.

4.

Do not try to compensate for the angle of the hull by fairing the epoxy

adhesive on the face of the transducer.

5.

Use the epoxy supplied with the in-hull transducer, or an equivalent

epoxy glue. Do not use any other type of adhesive, including silicone

or RTV adhesive.