17

INSTALLATION STEP 8

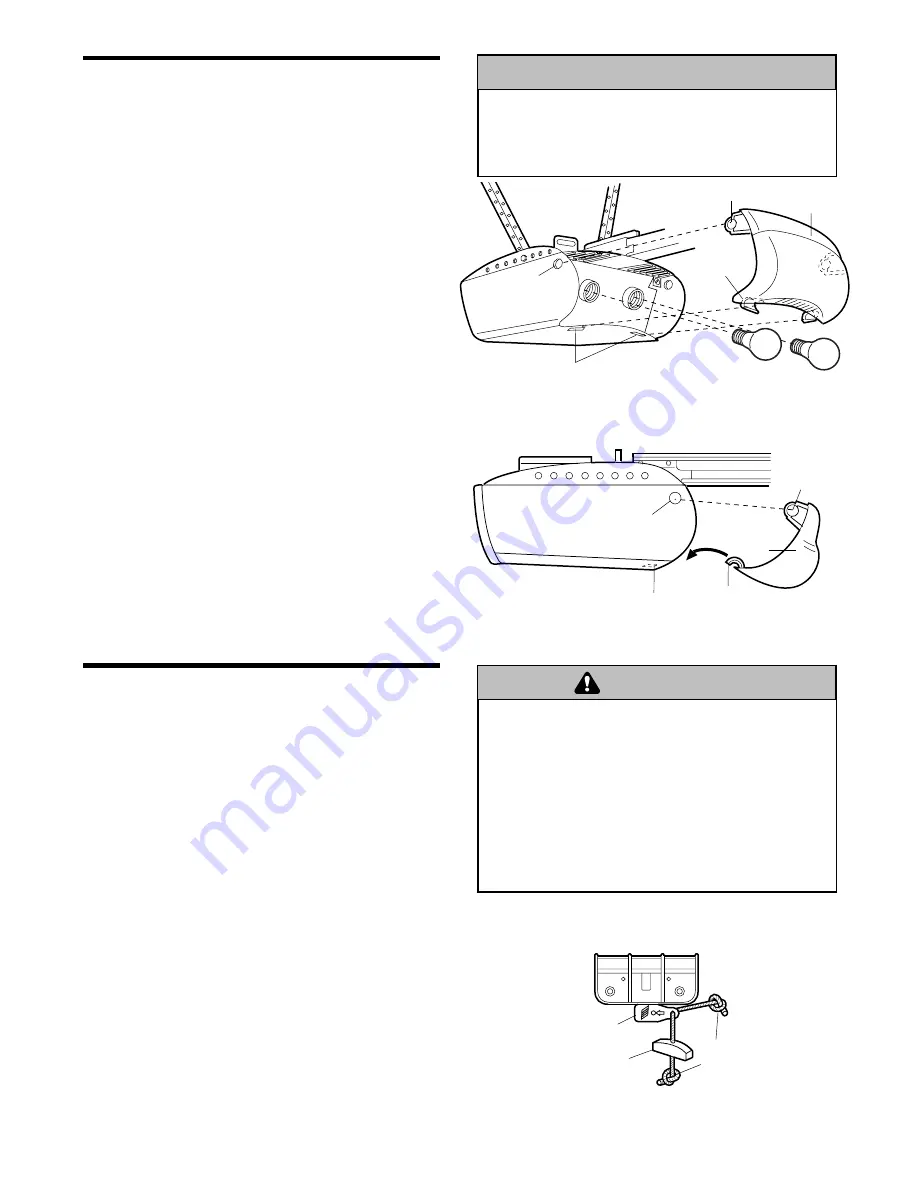

Install the Lights

• Install up to a 100 watt maximum light bulb in each

socket. The lights will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will turn OFF.

• Insert bottom lens tabs into slots on chassis. Tilt

towards chassis to engage top tabs, then drop

down gently into place.

• To remove, depress both top lens tabs. Tilt lens

slightly outward and down, then pull out to clear

bulbs. Use care to avoid snapping off bottom lens

tabs.

• Reverse the procedure to close the lens.

• If the bulbs burn out prematurely due to vibration,

replace with a Garage Door Opener bulb.

NOTE:

Use only standard light bulbs. The use of

short neck or speciality light bulbs may overheat the

endpanel or light socket.

INSTALLATION STEP 9

Attach the Emergency Release

Rope and Handle

• Thread one end of the rope through the hole in the

top of the red handle so “NOTICE” reads right side

up as shown. Secure with an overhand knot at

least 1" (2.5 cm) from the end of the rope to

prevent slipping.

• Thread the other end of the rope through the hole

in the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet (1.83 m)

above the floor. Secure with an overhand knot.

NOTE:

If it is necessary to cut the rope, heat seal

the cut end with a match or lighter to prevent

unraveling.

To prevent possible SERIOUS INJURY or DEATH from a

falling garage door:

• If possible, use emergency release handle to disengage

trolley ONLY when garage door is CLOSED. Weak or

broken springs or unbalanced door could result in an

open door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If rope

knot becomes untied, you could fall.

Bottom

Chassis Slots

Top Lens Tab

Bottom

Lens Tab

Bottom

Chassis Slot

Insert Bottom

Lens Tabs First

Top

Chassis Slot

Top

Lens Tab

Lens

Lens

Top

Chassis

Slot

NOTIC

E

Emergency

Release Handle

Overhand

Knot

Trolley

Release Arm

WARNING

CAUTION

WARNING

WARNING

To prevent possible OVERHEATING of the endpanel or

light socket,

• DO NOT use short neck or specialty light bulbs.

• DO NOT use halogen bulbs. Use ONLY incandescent.

WARNING

CAUTION

WARNING

WARNING