START-UP PROCEDURES

SECTION 1

.

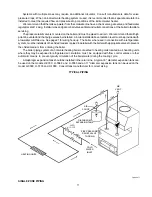

Filling the System

Fill system with water. Purge all air from the system

using purge valve sequence. After system is purged of

air, lower system pressure. Open valves for normal

system operation, fill system through feed pressure

regulator to minimum 12 PSI. Manually open air vent

on the compression tank until water appears, then close

vent.

On multiple zone systems, purge each zone sepa-

rately. Isolate the other zones while one zone is being

purged of air.

Flush system before putting into operation to as-

sure that foreign material does not damage pump seals.

SECTION 2

.

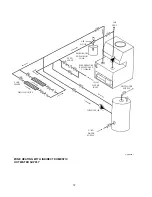

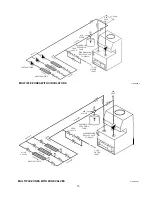

Checking the Circulator

Before lighting the boiler and after system is filled,

make sure that circulator is operating properly. Manual

gas valve should be off. By adjusting the wall thermo-

stat to the maximum setting, circulator should run

immediately and allow water to flow through the boiler

and the entire system.

NOTE:

Circulator motor supplied with the boiler does

not require lubrication.

CAUTION:

In case of a prolonged power failure during

freezing weather conditions, boiler and piping system

must be drained completely to avoid possible damage

to the heating system.

23