j) Reverse above procedure to re-install.

9. Fast Response Temperature Sensor Module

Replacement

a) Shut-off electrical power to the boiler.

b) Remove control cover screws and open

control compartment.

c) Disconnect wiring connections to the board.

d) Carefully pull out the control board from the

nylon pin supports.

e) Reverse above procedure to re-install.

10. Fast Response Temperature Sensor Probe

Replacement

a) Shut off electrical power to the boiler.

b) Shut off water supply to the boiler and open

drain valve to remove water to the sensor

probe level.

c) Remove control cover screws and open

control compartment.

d) Disconnect wire leads from control board.

e) Remove upper access panel.

f) Remove sensor probe from in/out header.

g) Reverse above procedure to re-install.

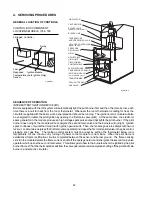

11. Circulator Replacement

a) Shut off electrical power to the boiler.

b) Shut off water supply and open drain valve

to remove water in the piping at the pump

level.

CAUTION

:

To avoid damage to electrical components

keep water from getting into the control compartments

and gas valve.

c) Disconnect wiring and conduit connections to

the pump.

d) Disconnect the by-pass tube connections to

the inlet flange.

e) Remove the nuts and bolts at the inlet and

outlet flanges. Remove old gaskets.

f) Remove the pump.

g) Reverse the above procedure to re-install.

Use new gaskets and make sure they are

seated properly when tightening the nuts

and bolts.

12. 2-Staged Controller (Models 90, 135 & 180)

a) Shut off electrical power to the boiler.

b) Remove control cover screws and open con-

trol compartment.

c) The control is factory set at 160°F. To reset

to another setting, use a small screw driver

and turn dial clockwise

to lower the

temperature or counter-clockwise

to

raise the setting.

d) To replace the staged controller, disconnect

the wiring connections.

e) Remove screws (2) holding the staged

controller.

f) Remove upper access panel.

g) Remove the wedge or retaining clip holding

the sensing bulb in the control well in the in/

out header.

h) Pull out the sensing bulb carefully from the

control well.

i) Remove the staged control with capillary

from unit.

j) Reverse above procedure to re-install.

6. REPLACEMENT PARTS LIST

NOTE:

To supply the correct part it is important that you

state the model number, serial number and type of gas

when applicable.

Any part returned for replacement under standard

company warranties must be properly tagged with

RAYPAK return parts tag, completely filled in with the

heater serial number, model number etc., and

shipped to the Company freight prepaid.

If determined defective by the Company and within

warranty, the part will be returned in kind or equal

substitution, freight collect. Credit will not be issued.

RAYPAK, INC.

31111 Agoura Road

Westlake Village, CA 91361-4699

34