13

4.7.3. Electronic Ignition Gas Valves

Figure 11. Location of Gas Pressure Adjustment

4.7.4. Water Connections

The heater requires water flow and positive pressure to

fire and operate properly. It must therefore be installed

downstream of the discharge side of the filter pump. A

typical installation is plumbed as follows:

1. The inlet side of the filter is plumbed directly to the

discharge side of the filter pump;

2. The outlet side of the filter is then plumbed to the

inlet of the heater; and

3. The outlet of the heater is plumbed to the return line

to the pool or spa. The pump, filter and heater are

thus plumbed in series.

Plumbing from the heater back to the pool or spa must not

have any valves or restriction that could prevent flow when

the pump is operating.

Heater must be located so that any water leaks will not

damage the structure of adjacent area. PVC pipe may be

glued directly into supplied CPVC header unions.

Model

Tubing

Input

1/2" (1.27 cm)

3/4" (1.91 cm)

1" (2.54 cm)

NAT

LPG

NAT

LPG

NAT

LPG

106

Cu

105,000 BTU/hr

(30.8 kW)

26' (8 m)

65' (20 m)

99' (30 m)

252' (77 m) 350' (107 m) 892' (272 m)

156

Cu

150,000 BTU/hr

(43.9 kW)

13' (4 m)

34' (10 m)

51' (16 m)

130' (40 m)

180' (55 m) 459' (140 m)

Table capacities are based upon use of sch 40 black iron pipe. For capacities using other materials, consult local code.

* Natural Gas 1000 BTU/FT

3

0.60 Specific Gravity @ 0.5" WC Pressure Drop (Gaz Naturel 3154.5 W/m

3

0.60 Densite @ 0.124 kPa Pressure Drop)

* Natural Gas 2500 BTU/FT

3

1.53 Specific Gravity @ 0.5" WC Pressure Drop (Gaz Naturel 7886.3 W/m

3

0.60 Densite @ 0.124 kPa Pressure Drop)

Table I.

Maximum Equivalent Pipe Length

4.7.5. Flow Rates

Model

Minimum

Maximum

106/156

20 GPM (75 L)

70 GPM (265 L)

Table H. Water Flow Rates

When the flow rates exceed the maximum 70 GPM

(265 L), an external auxiliary bypass valve is required. See

section "External Auxiliary Bypass Valve" on page 14

for details.

4.7.6. Polymer Headers

Before attaching the supplied 2" (5 cm) CPVC unions to

the In/Out header, make sure the O-rings are properly

seated in the grooves. Use AquaLube or equivalent non-

petroleum-based lubricant on the O-ring. Hand tighten the

unions. Glue PVC or CPVC piping directly to the unions.

In/Out Header

O-Ring

Tail Piece

Nut

2” Pipe

(5cm)

Drain Plug

Figure 12. In/Out Header for 2" (5 cm) Installation

In/Out Header

Hose Connector

Hose

Figure 13.

Optional In/Out Header for 1-1/2" (3.8 cm)

or

1-1/4" (3.2 cm) Hose Connection

If there is any possibility of back-siphoning when the

pump stops, it is recommended that a check valve (or

valves) also be installed in the system.

Summary of Contents for 106

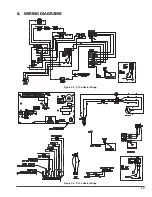

Page 23: ...23 6 WIRING DIAGRAMS Figure 35 P 106 Heater Wiring Figure 36 P 156 Heater Wiring...

Page 34: ...34 NOTES...

Page 35: ...35 NOTES...