14

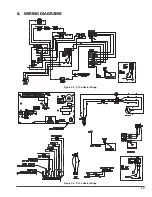

4.7.7. Internal Automatic Bypass Valve

A built-in automatic bypass valve is provided in the In/Out

header. The internal bypass valve automatically responds

to changes in water pressure in the piping system. The

proper amount of water flow is maintained through the

heater under varying pressures dictated by the conditions

of the pump and filter.

Bypass Disc

Spring

Bypass Body

Figure 14. Internal Automatic Bypass Valve

4.7.8. External Auxiliary Bypass Valve

An auxiliary bypass valve must be used when flow rates

exceed 70 GPM (265 LPM). Usually a high-performance

pump size larger than one horsepower will exceed

this flow rate. This valve is required to complement the

function of the automatic bypass valve, particularly when

starting the heater in winter or early spring when the spa

or pool temperature is below 50°F (10°C). It also serves to

eliminate needless pressure drop through the heater and

accompanying reduction in the flow rate to the spa jets,

etc.

FROM HEATER

TO HEATER

TO POOL/SPA

FROM POOL/SPA

FULL PORT

BALL VALVE

OR GLOBE

VALVE

BYPASS VALVE

Figure 15. Auxiliary Bypass Valve

4.7.9. Auxiliary Bypass Valve Adjustment

NOTE:

Do not use a gate valve as an auxiliary bypass valve.

To set bypass: With clean filter, adjustment is made by

touching the inlet and outlet pipes at the heater. Outlet

pipes should be slightly warmer than inlet and comfort-

able to the touch. If pipe is hot, close bypass; if cold, open

bypass.

4.7.10. Pressure Relief Valve Installation

To conform to local building codes, it may be necessary

to install a pressure relief valve. A 3/4” (1.9 cm) pressure

relief valve, having a capacity equal to or greater than the

BTUH input of the heater to be installed, is recommended

for this heater. The maximum pressure relief valve setting

is 125 psi (862 kPa). This relief valve needs to be installed

on the outlet pipe from the header as noted in Figure 16

below.

PIPE ONTO DISCHARGE SIDE OF PIPING

Figure 16. Pressure Relief Valve Installed

If required, this needs to be installed in a field-supplied

fitting external to the heater. The valve shall be installed in

a vertical position. Do not over-tighten. Install the pressure

relief valve hand tight plus 1/2 turn.

A

A

WARNING:

To avoid water damage or scalding due

to relief valve operation, drain pipe must be connected

to valve outlet and run to a safe place of discharge.

Drain pipe must be the same size as the valve discharge

connection throughout its entire length and must pitch

downward from the valve. No shut-off valve shall be

installed between the relief valve and the drain line.

The valve lever should be tripped at least once a year to

ensure that waterways are clear. If the relief valve does not

function properly, replace it immediately.

Flow (GPM)

Pressure Drop (ft of Head)

20

7.6

30

8.2

40

8.7

50

9.3

60

9.8

70

10.4

Table J.

Heat Exchanger Pressure Drop

Summary of Contents for 106

Page 23: ...23 6 WIRING DIAGRAMS Figure 35 P 106 Heater Wiring Figure 36 P 156 Heater Wiring...

Page 34: ...34 NOTES...

Page 35: ...35 NOTES...