22

On P-106 heaters, splice into the red/white wire to connect

the time clock. For P-156 heaters the fireman’s switch

connection is located on the 14-pin header connected to

the digital control board. Splice into the red wire jumper

tagged “Where necessary add “Fireman’s” switch circuit

here” to connect the time clock.

The fireman’s switch connection on both heaters

must be a dry contact and must not supply power to

the heater. Powering the fireman’s switch connection

externally may damage the heater, and is not covered

by warranty.

P-156 heaters: Do not exceed 50' (15.2 m) of total wiring

using 18 AWG stranded copper wire rated for 221°F

(105°C) minimum.

NOTE:

When using a time clock, the heater will display

“Clock/Fireman Sw” when the fireman’s switch is open,

indicating that the time clock has shut off the call for heat.

5.6. Post Start-Up Inspection

Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect

the heater and to replace any part of the control system

and any gas control which has been under water.

N’utilisez pas cet appareil s’il a ete plonge dans l’eau,

meme partiellement. Faites inspecter l’appareil par un

technicien qualifie et remplacez toute partie du systeme

de controle et toute commande qui ont ete plonges dans

l’eau.

A

A

WARNING:

Should overheating occur or the gas

supply fail to shut off, turn off the manual gas control to

the appliance.

A

A

AVERTISSEMENT

: En cas de surchauffe ou si

l’alimentation en gaz ne s’arrete pas, fermez manueiiement

ie robinet d’arret de l’admission de gaz.

Feel the inlet and outlet pipes. Outlet pipe should be only

slightly warmer than the inlet. It should not be hot.

With the heater on, remove the door and make a visual

check of the burner.

PILOT

Figure 33. IID Pilot Location

5.6.1. Cold Weather Operation

Moderate Climate

Heater operation can continue during short-term cold

spells. When temperatures are between 0° (-17°C) and

32°F (0°C), flow (continuous pump operation) must be

maintained.

A

A

CAUTION:

Do not use the heater to maintain water

temperatures just above freezing or for freeze protection.

When heater is used during freezing weather, care must

be taken to avoid freeze-ups. Continuous pump operation

is a must. Additional protection may be required. The

heater is not warranted against freeze-ups.

Cold Climate

Prolonged operation with water temperatures below 50°F

(10°C) is not recommended. When starting the heater with

water temperatures below 50°F (10°C), operate the heater

continuously until higher temperatures are reached.

Operating the heater for prolonged periods with pool

water below 50°F (10°C) can seriously damage the heater,

and is not covered by the warranty.

For cold climate areas, please follow the winterizing

procedures listed in the next section.

5.6.2. Winterizing the Heater

Heaters installed outdoors in freezing climate areas

may be shut down for the winter. Observe the following

procedure for winterizing the heater.

1. Turn off gas valve, manual gas valve, and electrical

supply to the heater.

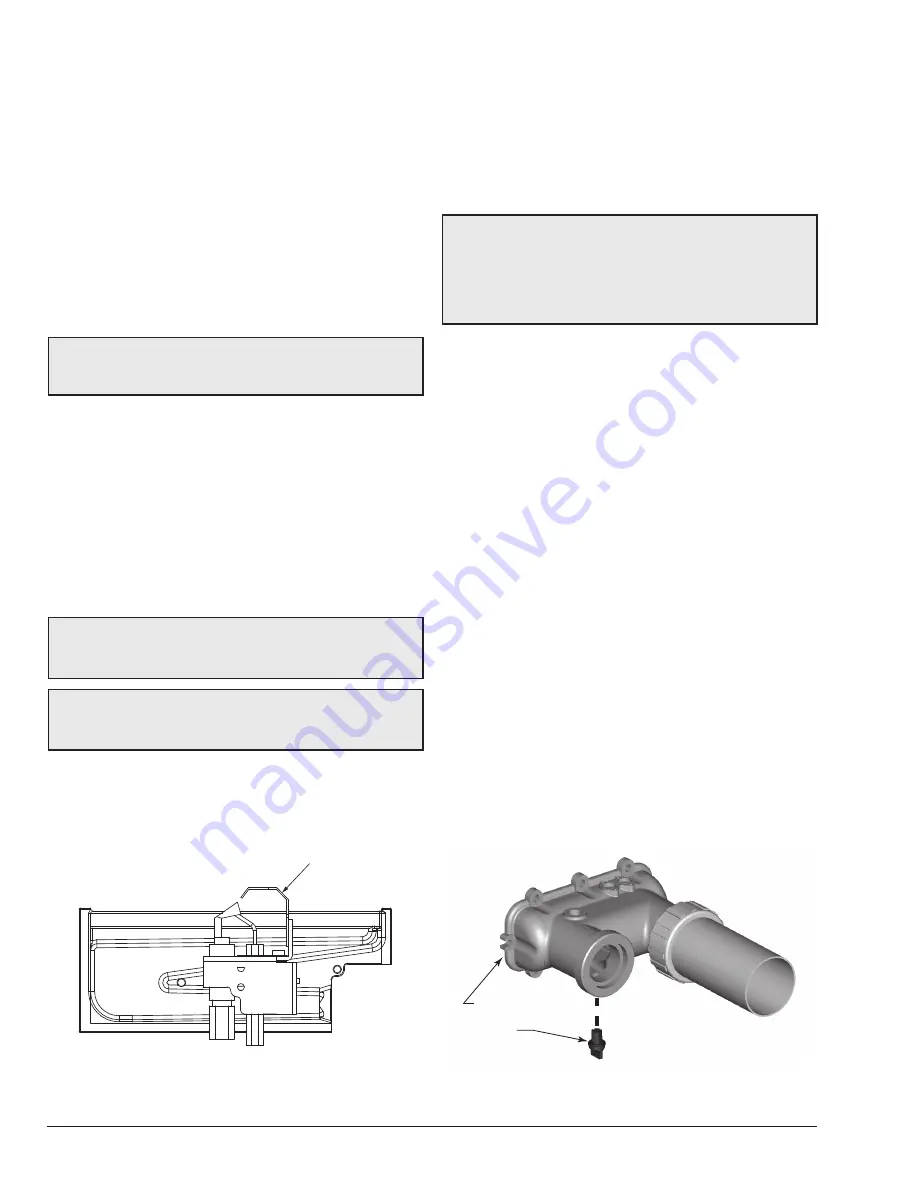

2. Open the drain plug located on the In/Out header,

under the water pipes.

3. Remove the 2 wires from the water pressure switch

and unscrew the water pressure switch to break any

vacuum in the system. Remove the pressure switch

and dry it before re-installing. Excessive moisture

in the pressure switch may freeze, damaging the

switch.

In/Out Header

Drain Plug

Figure 34. In/Out Header Drain Plug Location

Summary of Contents for 106

Page 23: ...23 6 WIRING DIAGRAMS Figure 35 P 106 Heater Wiring Figure 36 P 156 Heater Wiring...

Page 34: ...34 NOTES...

Page 35: ...35 NOTES...