24

7. MAINTENANCE

The following preventative maintenance is to be

performed one month after start-up and semi-annually

thereafter.

1. Inspect top of heater and drafthood for soot, a

sticky black substance around finned tubes and “V”

baffles, and open flue gas passageways. Any visible

soot should be cleaned for proper operation. See

"De-sooting Procedure" on page 26.

2. Clean main burners and pilot burner of dust and lint.

3. Inspect and operate all controls, gas valve and

pressure relief valve (if equipped).

4. Make visual check of the burner and pilot flames.

Flame pattern on the main burner and pilot is

illustrated in the Post Start-Up Inspection section.

Yellow flame means restriction of the air openings.

Lifting or blowing flame indicates high gas pressure.

Low flame means low gas pressure. Should these

occur, shut the heater off and contact your gas

supplier or qualified service agency.

5. On indoor heaters, clean room intake openings to

ensure adequate flow of combustion and ventilation

air.

6. Keep area around heater clear and free from

combustible materials, gasoline and other flammable

and corrosive vapors and liquids.

7.1. Service

Verify proper operation after servicing.

S’assurer que l’appareil fonctionne adéquatement une

fois l’entretien terminé.

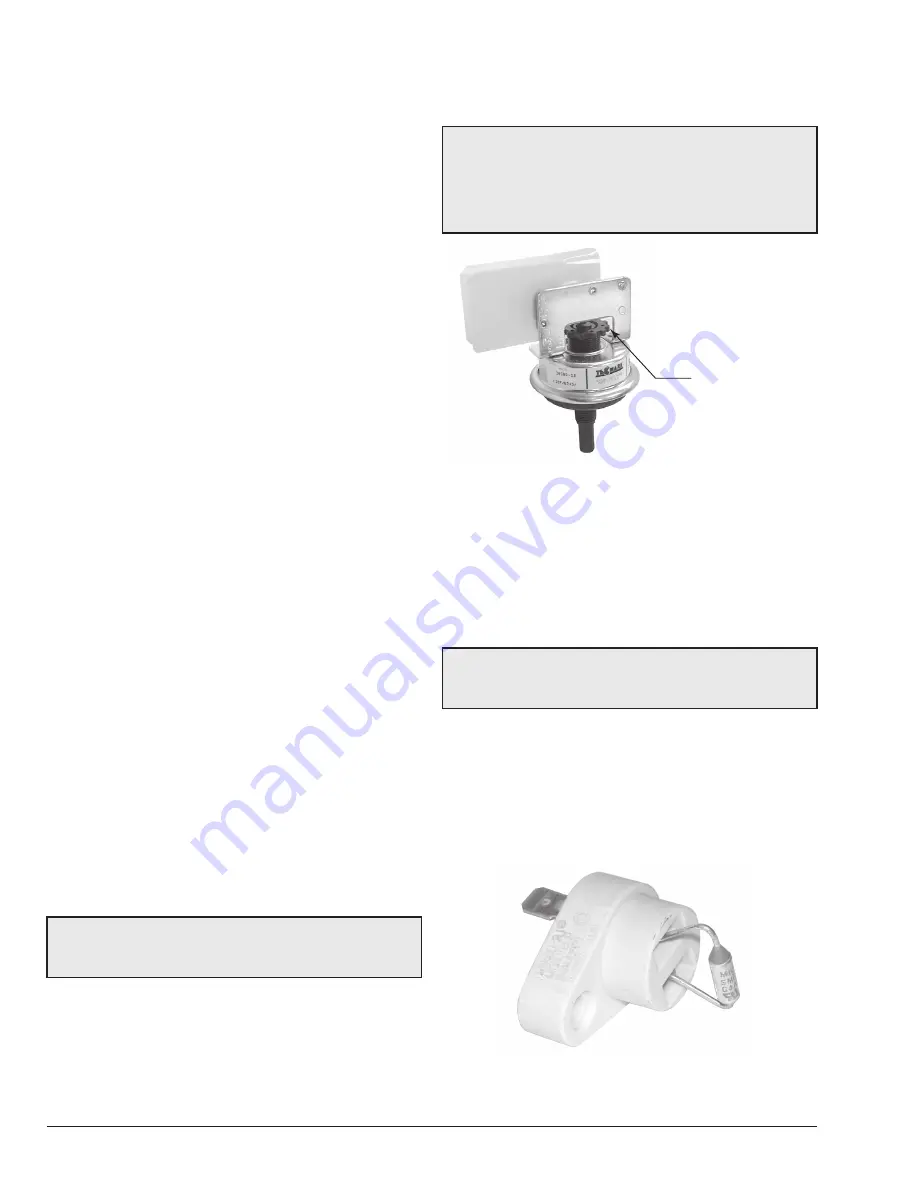

7.1.1. Water Pressure Switch

The water pressure switch, ensures that the heater

operates only when the filter pump is in operation. It

is located on the In/Out header. It is factory set at 1.75

PSI (12kPa) for deck-level installations. When the heater

is located below the level of the spa or pool, it may be

necessary to adjust the pressure switch to compensate

for the no-flow static head. If it is necessary to adjust the

water pressure switch, utilize the following procedure.

A

A

CAUTION:

Do not adjust the pressure switch until all

air has been evacuated from the system and the water

flow rate meets the requirements listed in Table I.

Water Pressure Switch Adjustment

1. With pump and heater on, turn adjustment knob

clockwise until a click is heard from the gas valve.

2. Turn adjustment knob counter-clockwise 1/4 turn.

3. Turn pump off and on several times. Heater should

shut off immediately. If it does not, repeat the above

steps.

NOTE:

If heater is installed outside of the limits shown, a

higher pressure rated 11 psi (76 kPa) switch may be used.

A flow switch, mounted and wired adjacent to the heater,

may be used in place of the factory mounted pressure

switch. See Illustrated Parts List for 11 psi (76 kPa) water

pressure switch.

Adjustment Knob

Figure 37. Water Pressure Switch Adjustment

7.1.2. Two-Speed Pumps

In some cases, the flow on the low-speed is insufficient

to operate the heater. This is apparent when the water

pressure switch cannot be further adjusted or if the heater

makes banging noises or shuts off on high limit. In these

cases, the pump must be run at high speed when heating

the water.

A

A

CAUTION:

Do not operate the heater without the

function of a properly adjusted water pressure switch or

flow switch.

7.1.3. Pilot Safety

The heater employs a pilot safety which closes the main

gas valve within 8/10ths of a second whenever the pilot

flame is interrupted. The pilot flame is automatically lit

when the device is powered. The heater performs its own

safety check and opens the main valve only after the pilot

is proven to be lit.

Figure 38. Flame Roll-Out Safety Switch

Summary of Contents for 106

Page 23: ...23 6 WIRING DIAGRAMS Figure 35 P 106 Heater Wiring Figure 36 P 156 Heater Wiring...

Page 34: ...34 NOTES...

Page 35: ...35 NOTES...