9

Model No.

VAC - Phase -

Hz

Minimum

Circuit

Ampacity

(A)

Breaker

Size

(A)

Min Max

5350

208/230 - 1 - 60

40.0

50

60

6350/6350HC

42.0

8350/8350HC

208/230 - 3 - 60

34.0

40

50

10355

208/230 - 1 - 60

42.0

40

60

Table B. Electrical Power Requirements

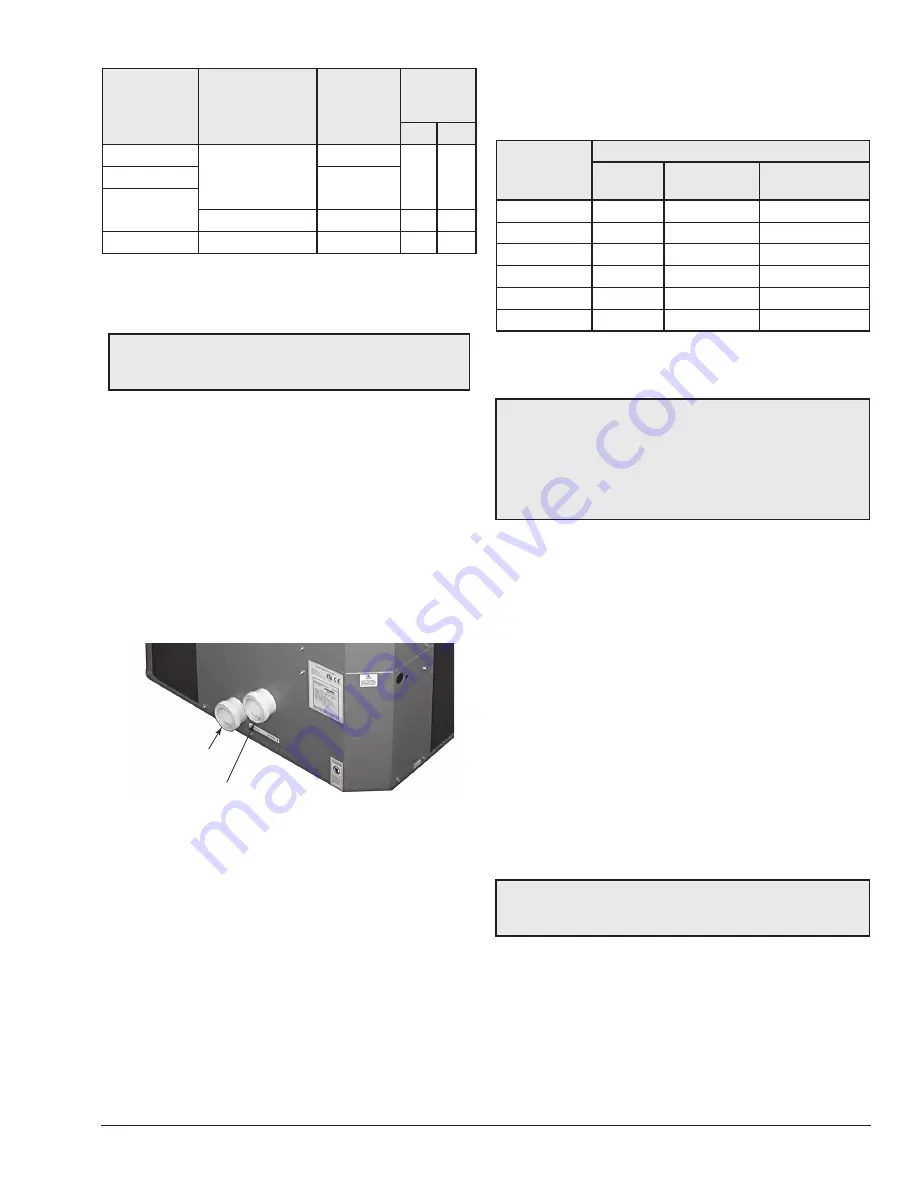

6. WATER CONNECTIONS

CAUTION:

The heater inlet and outlet connections

are NOT interchangeable. They must be connected as

instructed below.

1. Connect the heater in the return water line between

the filter and the pool/spa. See the Plumbing

Diagrams beginning on

page

15

.

2. Connect the filter outlet to the fitting marked WATER

IN at the bottom front of the unit.

3. Connect the fitting marked WATER OUT to the return

piping to the pool/spa. Unit inlet/outlet connection

fittings are 2" PVC unions.

Water connections from the unit to the main return line can

be PVC pipe or flexible pipe approved for the purpose and,

in either case, should be at least equal in size to the main

pool/spa circulation piping.

WATER IN

WATER OUT

Figure 4. Water Connections

4. In cold weather (freeze zone) areas, shutoff valves

(ball or gate type) must be installed at the unit inlet

and outlet to facilitate service and cold weather drain-

down.

5. Operate the pump and check the system for leaks.

7. PRESSURE DROP

For system pressure drop information, refer to

Table C

below.

Flow

gpm (lpm)

Pressure Drop PSI (kPa)

5350

6350/6350HC 8350/8350HC/

8360

30 min. (114) 4 (27.6)

6 (41.4)

9 (62.1)

40 (151)

7 (48.3)

9 (62.1)

9 (62.1)

50 (189)

10 (68.9)

10 (68.9)

10 (68.9)

60 (227)

11 (75.8)

11 (75.8)

11 (75.8)

70 (265)

12 (82.7)

12 (82.7)

12 (82.7)

80 max. (303) 13 (89.6)

13 (89.6)

13 (89.6)

Multiply the pressure drop in PSI by 2.3067 to yield the pressure drop

in Ft. H2O Head (TDH).

Table C. Pressure Drop Across Heater

A

WARNING:

Install a check valve and/or a Hartford

loop AFTER the heater and BEFORE any chlorinating

devices. Install any automatic chemical feeders AFTER

the heater. Improper installation of any type of automatic

chemical feeders can result in serious damage to, or

premature failure of the heater. Such damage will not be

covered under warranty.

8. CONTROLS & INDICATOR

LAMPS (ANALOG

MODELS)

Your analog heater incorporates safety controls and

indicators to ensure its safe, reliable operation (for models

with digital controls, see

page 11

).

Water Pressure Switch

: Prevents operation when the

pump is OFF. The unit requires 5 PSI (34.5 kPa) minimum

pressure.

Water Temperature Control

: Pool/spa water temperature

is controlled by the heater thermostat on the unit control

panel, which contains a switch and 2 thermostats, one

for setting a heat spa temperature and the other for a

swimming pool temperature. The switch can operate an

optional external control system, or can switch between

thermostats for pool or spa.

NOTE:

The heater will not run when the Remote position

is selected on the Pool/Spa selector switch and there is

no remote control system attached.

Defrost Switch

: Prevents operation of the heater if

ambient air temperature falls below a predetermined safe

minimum (approximately 42°F [5.6°C]).

Delay Time

r: Prevents the compressor from short-cycling,

which could damage or destroy the hermetic motor/

compressor. Upon water temperature control satisfaction,

or other circuit interruptions, this solid-state device will

prevent compressor restart for approximately 5-minutes.

Summary of Contents for 5350 Series

Page 20: ...20 H C F DUAL CAPACITOR V V 208V 230V Single Phase Digital Models 5350 6350 8350 8360...

Page 21: ...21 208V 230V 3 Phase Analog Models 5350 6350 8350...

Page 22: ...22 208V 230V 3 Phase Digital Models 5350 6350 8350...

Page 23: ...23 460V 3 Phase Analog Model 8354...

Page 26: ...26...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30 NOTES Raypak Inc 2151 Eastman Avenue Oxnard CA 93030 805 278 5300 www raypak com...

Page 60: ...30 NOTES Raypak Inc 2151 Eastman Avenue Oxnard CA 93030 805 278 5300 www raypak com...