25

ured to operate in an on-off firing mode. This

means that you will connect a single-pole control

to stage one of the CPW board. Then jumper the

remaining firing stages. For example, if your

heater is a Model 1532B, you will jumper stages

two, three and four. Then your heater will either be

on at full fire, or it will be off.

2.

For 2-stage controller connections, connect each

stage of the control to the corresponding stage of

the CPW board in the heater, i.e., stage 1 of the

heater to stage 1 of the control; stage 2 of the

heater to stage 2 of the control, as shown in Fig.

22 and Fig. 25. Set the operating control to the

set-point at which you want the heater to maintain.

Ensure that the sensing bulb of the control is at the

point in the system that will best maintain the tem-

perature you want. For example, when you are

heating a tank of water, you want the operating

control sensor bulb in the tank.

3.

For single-stage controller connections, attach the

stage 1 connections on heater 1 to the tankstat per

Fig. 26.

Heater must be electrically grounded in accordance

with the NEC, and CSA C22.1 C.E.C. Part 1 in

Canada.

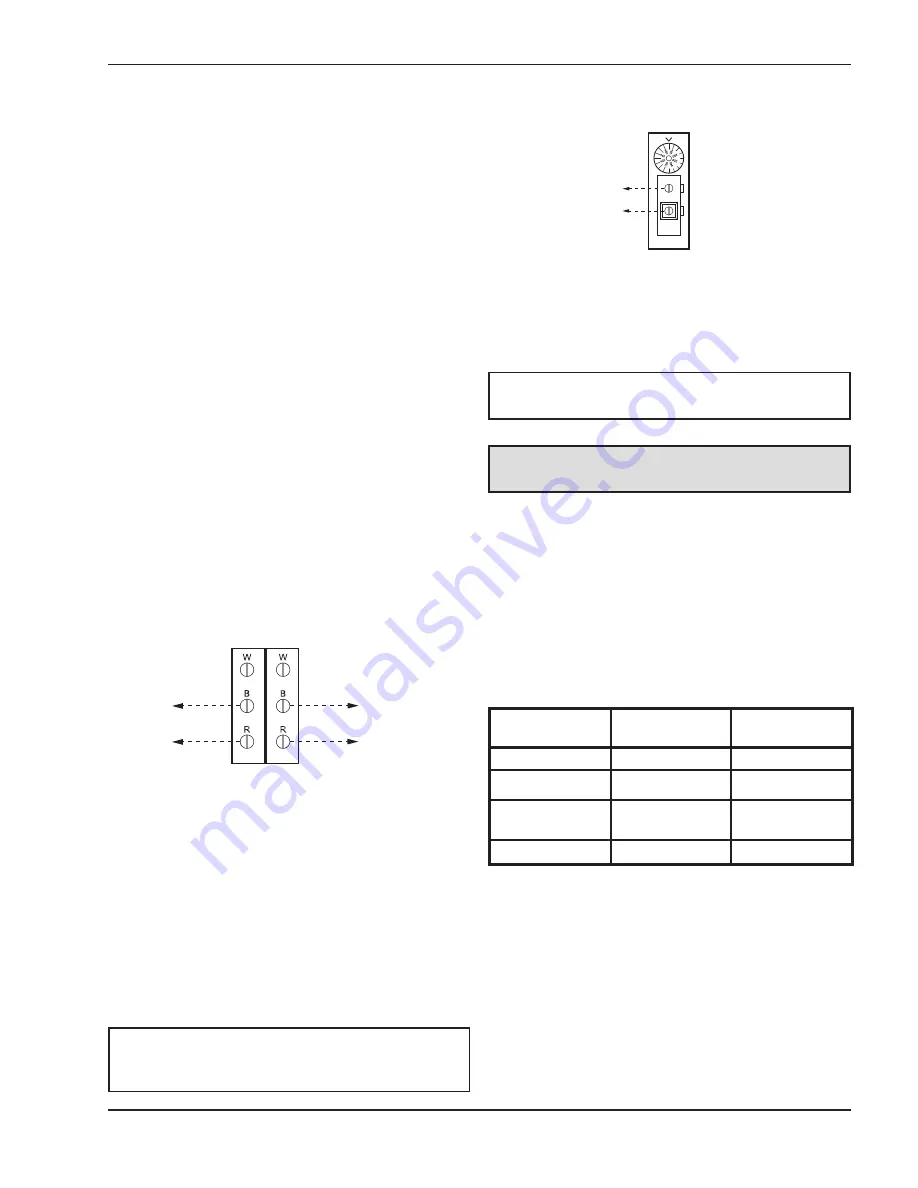

2-STAGE

TANKSTAT

STAGE 1

CONNECTION

STAGE 2 CONNECTION OR

STAGE 1 CONNECTION

OF HEATER 2

ATTACH STAGE 1 CONNECTIONS ON HEATER

TO STAGE 1 CONNECTION ON TANKSTAT.

ATTACH STAGE 2 CONNECTIONS OR

STAGE 1 CONNECTION OF HEATER 2

TO STAGE 2 CONNECTIONON TANKSTAT

AS SHOWN IN THE DIAGRAM.

Fig. 25: 2-Stage Tankstat

SINGLE

STAGE

TANKSTAT

STAGE 1

CONNECTION

ATTACH STAGE 1 CONNECTIONS

ON HEATER TO THE SINGLE STAGE

TANKSTAT AS SHOWN IN THE DIAGRAM ABOVE.

Fig. 26: Single-Stage Tankstat

Venting

General

Flue Exhaust Tee

An optional Flue Exhaust Tee is available to facilitate

horizontal venting. Any reference to horizontal venting

that exits the back of the heater requires this tee. Refer

to Table J for the appropriate kit for your model.

Appliance Categories

Heaters are divided into four categories based on the

pressure produced in the exhaust and the likelihood of

condensate production in the vent.

Category I

– A heater which operates with a non-pos-

itive vent static pressure and with a vent gas

temperature that avoids excessive condensate pro-

duction in the vent.

NOTE:

For 87%-efficiency boilers, see special

instructions on page 43.

CAUTION:

Proper installation of flue venting is criti-

cal for the safe and efficient operation of the heater.

Consult the wiring diagram shipped with the heater in

the instruction packet or at the end of this section. The

stage-selector terminals are for the remote tank con-

trol through the heater’s 24 VAC transformer.

DO NOT

attach any voltage to the stage-selector terminals.

Before starting the heater, check to ensure proper volt-

age to the heater and pump.

NOTE:

If any of the original wire supplied with the

heater must be replaced, it must be replaced with

similar sized 105°C wire or its equivalent.

Model

Diameter

Order Number

992B

10”

011841

1262B, 1532B

12”

011842

1802B, 2002B,

2072B

14”

011843

2342B

16”

011844

Table J: Flue Exhaust Tee Kits