17

Pressure Drop in Feet of Head

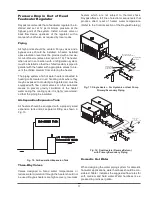

Feedwater Regulator

Raypak recommends that a feedwater regulator be in-

stalled and set at 12 psi minimum pressure at the

highest point of the system. Install a check valve or

back flow device upstream of the regulator, with a

manual shut-off valve as required by local codes.

Piping

All high points should be vented. Purge valves and a

bypass valve should be installed. A heater installed

above radiation level must be provided with a low wa-

ter cut-off device (sales order option F-10). The heater,

when used in connection with a refrigeration system,

must be installed so that the chilled medium is piped in

parallel with the heater with appropriate valves to pre-

vent the chilled medium from entering the heater.

The piping system of a hot water heater connected to

heating coils located in air handling units where they

may be exposed to circulating refrigerated air, must be

equipped with flow control valves or other automatic

means to prevent gravity circulation of the heater

water during the cooling cycle. It is highly recommend-

ed that the piping be insulated.

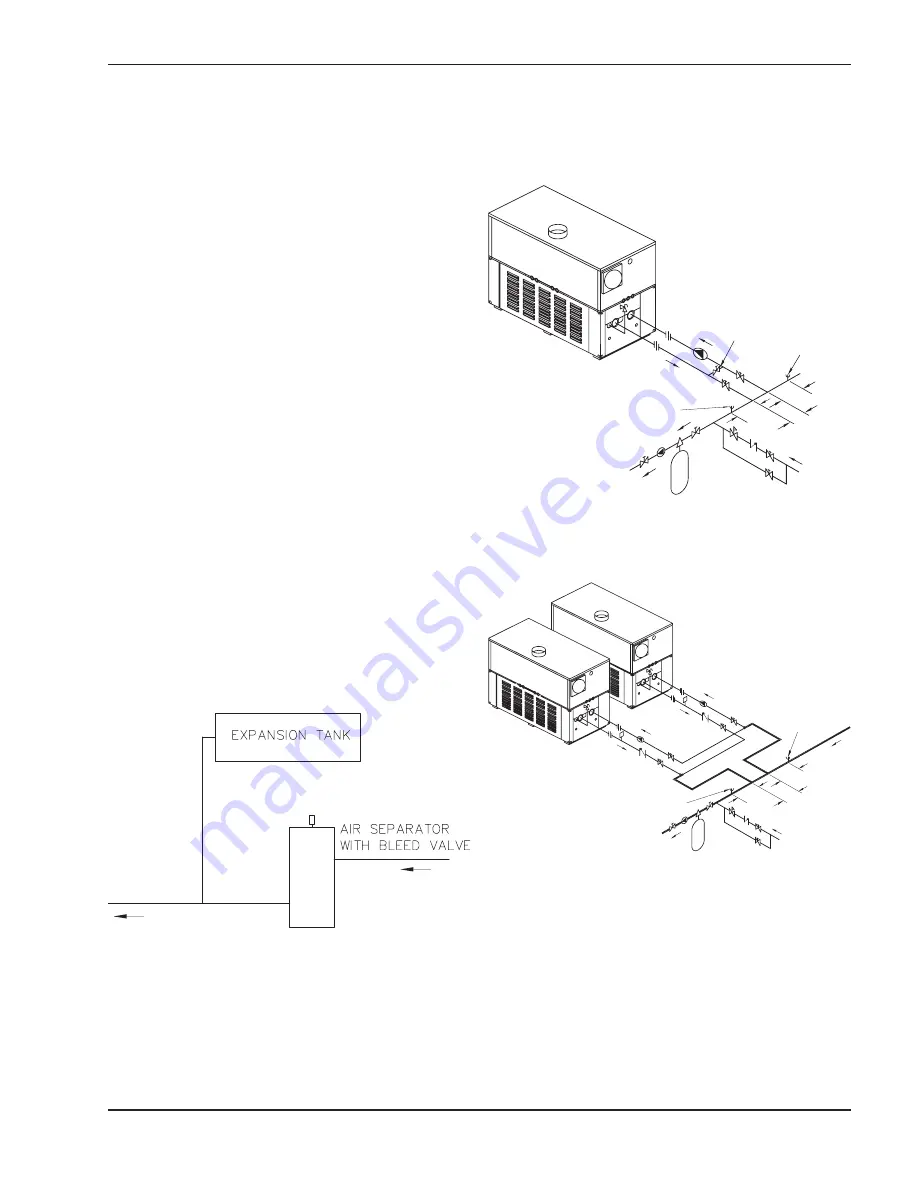

Air-Separation/Expansion Tank

All heaters should be equipped with a properly sized

expansion tank and air separator fitting as shown in

Fig. 10.

Three-Way Valves

Valves designed to blend water temperatures or

reduce water circulation through the heater should not

be used. Raypak heaters are high-recovery, low-mass

Fig. 10: Air-Separation/Expansion Tank

heaters which are not subject to thermal shock.

Raypak offers a full line of electronic sequencers that

produce direct reset of heater water temperature.

(Refer to the Controls section of the Raypak Catalog.)

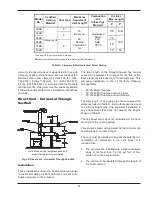

Domestic Hot Water

When designing the water piping system for domestic

hot water applications, water hardness should be con-

sidered. Table I indicates the suggested flow rates for

soft, medium and hard water. Water hardness is ex-

pressed in grains per gallon.

NOTE: BYPASS FOR

LOW TEMP SYSTEMS ONLY

SYSTEM SENSOR

(HEAT PUMP)

12” MAX

OR MIN FEASIBLE

5’ MAX

5’ MAX

SYSTEM SENSOR

(4:1 TURNDOWN

OR GREATER)

Fig. 11: Single Heater - For Hydronic or Heat Pump

Primary/Secondary Piping

12” MAX

OR MIN FEASIBLE

SYSTEM SENSOR

(LESS THAN

4:1 TURNDOWN)

5’ MAX

5’ MAX

SYSTEM SENSOR

(4:1 TURNDOWN

OR GREATER)

Fig. 12: Dual Heaters (Reverse/Return)

with Primary/Secondary Piping

Summary of Contents for HI DELTA 302B

Page 45: ...45 Wiring Diagram...

Page 59: ...59...