at test pressures equal to or less than 1/2 psi (3.45

kPa). Relieve test pressure in the gas supply line prior

to reconnecting the heater and its manual shut-off

valve to the gas supply line.

FAILURE TO FOLLOW

THIS PROCEDURE MAY DAMAGE THE GAS

VALVES

. Over pressurized gas valves are not cov-

ered by warranty. The heater and its gas connections

shall be leak-tested before placing the appliance in

operation. Use soapy water for leak test. DO NOT use

an open flame.

Reversing Gas Supply Connection

Reversing the standard fuel connection from the left-

hand to the right-hand side is a simple field operation.

1. Disconnect all electrical power from the heater (if

applicable).

2. Disconnect the main gas pipe from the heater (if

applicable).

3. Remove the left and right front panels from the

heater.

4. Locate the main gas line that traverses across the

heater above the manifold risers.

5. Remove the pipe cap from the right-hand end of

the main gas line.

21

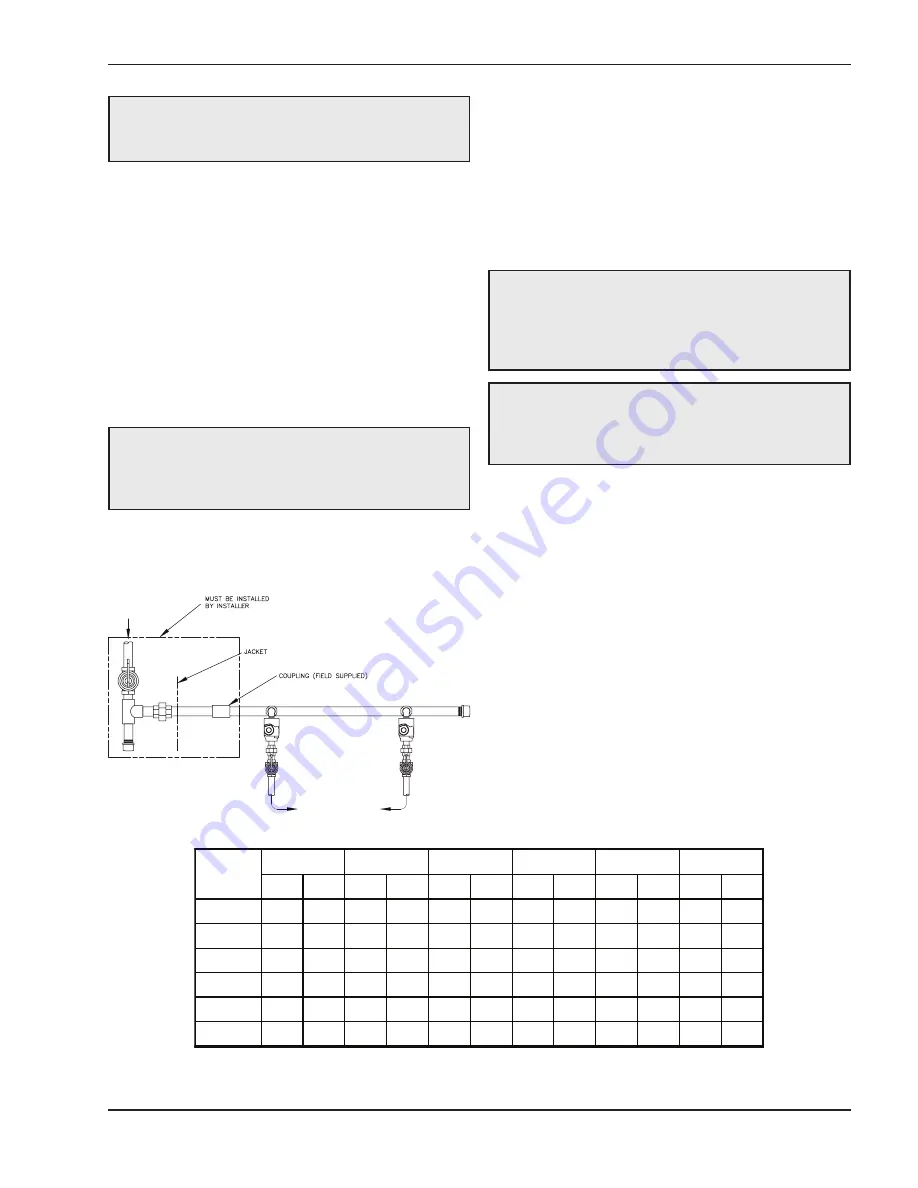

Gas Supply

Gas piping must have a sediment trap ahead of the

heater gas controls, and a manual shut-off valve lo-

cated outside the heater jacket. It is recommended

that a union be installed in the gas supply piping adja-

cent to the heater for servicing. A pounds-to-inches

regulator must be installed to reduce the gas supply

pressure to a maximum of 10.5 in. WC for natural gas

and 13.0 in. WC for propane gas. The regulator should

be placed a minimum distance of 10 times the pipe

diameter up-stream of the heater gas controls. Refer

to Table K for maximum pipe lengths.

Gas Supply Connection

The heater must be isolated from the gas supply pip-

ing system by closing the manual shut-off valve during

any pressure testing of the gas supply piping system

CAUTION:

The heater must be disconnected from

the gas supply during any pressure testing of the gas

supply system at test pressures in excess of 1/2 psi

(3.45 kPa).

Fig. 16: Gas Supply Connection

CAUTION:

Do not use Teflon tape on gas line pipe

thread. A pipe compound rated for use with natural

and propane gases is recommended. Apply

sparingly only on male pipe ends, leaving the two

end threads bare.

CAUTION:

Support gas supply piping with

hangers, not by the heater or its accessories. Make

sure the gas piping is protected from physical

damage and freezing, where required.

3/4"

1”

1-1/4”

1-1/2”

2”

2-1/2”

Model

No.

N

P

N

P

N

P

N

P

N

P

N

P

302B

15

25

35

85

150

380

360

--

--

--

--

--

402B

--

15

25

60

100

260

250

--

--

--

--

--

502B

--

--

--

--

65

150

130

360

500

--

--

--

652B

--

--

--

--

45

100

95

250

340

--

--

--

752B

--

--

--

--

35

80

75

180

260

600

--

--

902B

--

--

--

--

20

45

45

110

150

360

400

--

Table K: Maximum Equivalent Pipe Length

DANGER:

Make sure the gas on which the heater

will operate is the same type as specified on the

heater’s rating plate.

Natural gas – 1,000 BTU per ft

3

, .60 specific gravity at 0.5 in. WC pressure drop

Propane gas – 2,500 BTU per ft

3

, 1.53 specific gravity at 0.6 in. WC pressure drop

Summary of Contents for HI DELTA 302B

Page 45: ...45 Wiring Diagram...

Page 59: ...59...