46

START-UP

Pre Start-up

Filling System (Heating Boilers)

Fill system with water. Purge all air from the system.

Lower system pressure. Open valves for normal sys-

tem operation, and fill system through feed pressure.

Manually open air vent on the compression tank until

water appears, then close vent.

Air Purge (Domestic Hot Water

Heaters)

Purge all air from system before lighting heater. This

can be normally accomplished by opening a down-

stream valve.

Venting System Inspection

1. Check all vent pipe connections and flue pipe ma-

terial.

2. Make sure vent terminations are installed per code

and are clear of all debris or blockage.

For Your Safety

This appliance has a hot surface igniter. It is equipped

with an ignition device which automatically lights the

burners. Do not try to light the burners by hand.

BEFORE OPERATING, smell all around the appliance

area for gas. Be sure to smell near the floor because

some gas is heavier than air and will settle on the floor.

WARNING:

If you do not follow these instructions

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any

telephone in your building.

•

Immediately call your gas supplier from a neigh-

bor’s telephone. Follow the gas supplier’s

instructions.

•

If you cannot reach your gas supplier, call the fire

department.

•

Use only your hand to push in or turn the gas con-

trol knob. Never use tools. If the knob will not turn

by hand, do not try to repair it, call a qualified serv-

ice technician. Forced or attempted repair may

result in a fire or explosion.

•

Do not use this appliance if any part has been

under water, immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

•

Check around unit for debris and remove com-

bustible products, i.e. gasoline, etc.

Pre Start-up Check

1. Verify heater is filled with water.

2. Check system piping for leaks. If found, repair

immediately.

3. Vent air from system. Air in system can interfere

with water circulation.

4. Purge air from gas line up to heater.

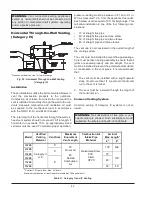

Initial Start-up

Tools Needed

•

(1) 12-0-12, 24” scale U-tube manometer

•

(4) 6-0-6, 12” scale U-tube manometers (mini-

mum)

•

(1) Screwdriver

•

(1) Multi-meter

•

(1) 3/16” Allen wrench

NOTE:

Digital manometers are not recommended.

NOTE:

Boil-out information:

The oils, grease and

other contaminates found in some gas fired boilers

are not present in the water side of a Raypak

appliance. Most boil-out procedures require the use

of an alkaline (high pH) cleaning agent that will

damage the copper finned tubes of the heat

exchanger. Heat exchangers damaged due to boil-

out are not covered under warranty.

Summary of Contents for HI DELTA 302B

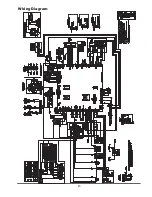

Page 45: ...45 Wiring Diagram...

Page 59: ...59...