47

Preparation

Check Power Supply

With multi-meter at incoming power, check voltage

between:

Hot - Common (≈120 VAC)

Hot - Ground (≈120 VAC)

Common - Ground (< 1 VAC)

Attach Manometers to Measure Pressures

1. Turn off main gas valve.

2. Attach 24” scale manometer to the first main gas

shut-off valve pressure tapping.

3. Attach (1) 12” scale manometer to the outlet side

of the second main gas shut-off valve pressure

tapping.

4. Attach (1) 12” scale manometer near the fan-prov-

ing switch. Pull black cap from air pressure switch

tee and connect the manometer. NOTE: Retain

caps for reinstallation later.

Check Gas Supply Pressure

1. Slowly turn on main gas shut-off valve.

2. Read the gas supply pressure from the manome-

ter; minimum supply pressure for natural gas is 5.0

in. WC, recommended supply is 7.0 in. WC, mini-

mum supply pressure for propane gas is 11.0 in.

WC (dynamic readings, all stages firing).

3. If the pressure is > 14.0 in. WC, turn off the valve.

4. Check if the service regulator is installed and/or

adjust the service regulator.

WARNING:

Do not turn on gas at this time.

WARNING:

If Common - Ground is > 1 VAC,

STOP: Contact electrician to correct ground failure.

Failure to do this may burn out 120V-24V

transformer, or may cause other safety control

damage or failure.

Start-Up

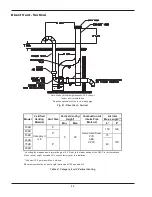

Blower Adjustment

1. Turn off power.

2. Unplug cap at pressure switches and connect ma-

nometer(s) to the tee.

3. Close all manual firing valves.

4. Turn power on.

5. Check manometers attached to fan pressure

switch. The reading should be 1.4 ± .1 in. WC for

propane gas and natural gas. If not, adjust the air

shutter on the blowers to attain the correct value.

6. Turn power off.

7. Reconnect this cap.

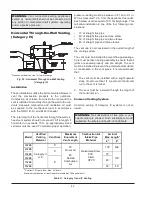

Main Burner Adjustment

1. Turn off unit.

2. Open manual firing valves.

3. Turn on the unit, wait 15 seconds, and the igniter

should glow. Look into sight glass located at each

end of the heater to check igniter operation. Gas

valves should open in 45-60 seconds.

4. If burner does not light on first trial. It will retry, up

to three times.

5. Main burner ignition: Check manifold gas pressure

at gas valve outlet pressure tap. This should read

3.5 ± 0.1 in. WC for natural gas and 10.5 ± 0.1 in.

WC for propane gas.

6. If the pressure reading differs by more than ± 0.1

in. WC, remove screw cover from the gas pres-

sure regulator and adjust main burner manifold

pressure. Replace the screw cover. Repeat steps

2 to 5 on other valves as necessary.

CAUTION:

Special manifold and air settings may

be required. Verify rating plate and blower housing.

Summary of Contents for HI DELTA 302B

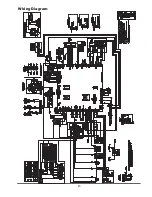

Page 45: ...45 Wiring Diagram...

Page 59: ...59...