54

APPENDIX

Inside Air Contamination

All heaters experience some condensation during

start-up. The condensate from flue gas is acidic.

Combustion air can be contaminated by certain vapors

in the air which raise the acidity of the condensate.

Higher acidity levels attack many materials including

stainless steel, which is commonly used in high effi-

ciency systems. The heater can be supplied with

corrosion-resistant, non-metallic intake air vent materi-

al. You may, however, choose to use outside

combustion air for one or more of these reasons:

1. Installation is in an area containing contaminants

listed below which will induce acidic condensation.

2. You want to reduce infiltration into your building

through openings around windows and doors.

3. You are using AL29-4C stainless steel vent pipe,

which is more corrosion-resistant than standard

metallic vent pipe. In extremely contaminated ar-

eas, this may also experience deterioration.

Products causing contaminated combustion air:

•

spray cans containing chloro/fluorocarbons

•

permanent wave solutions

•

chlorinated waxes/cleaners

•

chlorine-based swimming pool chemicals

•

calcium chloride used for thawing

•

sodium chloride used for water softening

•

refrigerant leaks

•

paint or varnish removers

•

hydrochloric acid/muriatic acid

•

cements and glues

•

antistatic fabric softeners used in clothes dryers

•

chloride-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

•

adhesives used to fasten building products

•

similar products

Areas where contaminated combustion air commonly

exists:

•

dry cleaning/laundry areas

•

metal fabrication plants

•

beauty shops

•

refrigeration repair shops

•

photo processing plants

•

auto body shops

•

plastic manufacturing plants

•

furniture refinishing areas and establishments

•

new building construction

•

remodeling areas

•

open pit skimmers

Check for areas and products listed above before in-

stalling heater. If found:

•

remove products permanently, OR

•

install TruSeal direct vent

Summary of Contents for HI DELTA 302B

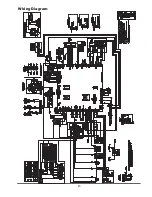

Page 45: ...45 Wiring Diagram...

Page 59: ...59...