7

INSTALLING THE

CONTROL

The control should be mounted on a wall, preferably at

eye level with AC power as close as possible.

Consider the length of cable required for routing along

walls, along pipes, and for connecting the temperature

sensors.

Notice on the bottom of the control that two of the five

knockouts have been removed for routing of cables. If

you want to use one or more of the other knockouts,

these should be removed before mounting the control

onto the wall.

Attaching the Temperature

Sensors

To get an accurate reading of the water temperatures,

the sensors must be in good thermal contact with the

pipe. Follow this procedure when connecting the tem-

perature sensors.

Procedure for Connecting Temperature Sensors to

Pipes:

1. Remove any existing insulation.

2. Clean the pipe surface using sandpaper.

3. Apply thermal conducting paste to the pipe sur-

face.

4. Fasten the sensor tightly to the pipe using the

black cable tie.

5. Attach 18 AWG shielded cable to the 6 in. leads

using wire nuts or electrical tape.

6. Fasten the cable to the pipe using a second black

cable tie.

7. Replace the existing insulation or wrap thermal

insulation tape around the pipe.

Overlap each

turn and DO NOT STRETCH the tape.

On the sensor end, roll the shielding and tape so it will

not contact a conductor. On the control end, the shield

should be grounded.

Do not ground both ends of

the shielding.

Avoid routing wiring on or near other electrical wires,

conduit, motors, spark igniters or other sources of

high, intermittent voltage or current. EMI (spikes) can

disrupt information flow and retention.

Procedure for Installing Supply Sensor in Tank:

1. Install sensor into dry well utilizing thermal con-

ductive paste.

2. Install dry well into tank stat opening.

Providing 24 VAC Power to the

Control

The RayTemp requires an external power transformer

connected at terminals one and two. Complete and

check all wiring before connecting this transformer.

The transformer must be rated for 24 VAC at 16 VA or

higher.

When 24 VAC power is applied to the control the LCD

display will be blank for a few seconds. During this

time the RayTemp is configuring any modem that may

be connected. Afterwards, the opening screen

appears, which identifies the model number, type of

control, software version, and copyright notice.

CAUTION:

DO NOT connect power until all wiring

is complete and checked.

CAUTION:

DO NOT connect 120 VAC to the

RayTemp!!! Resulting damage will void your

warranty.

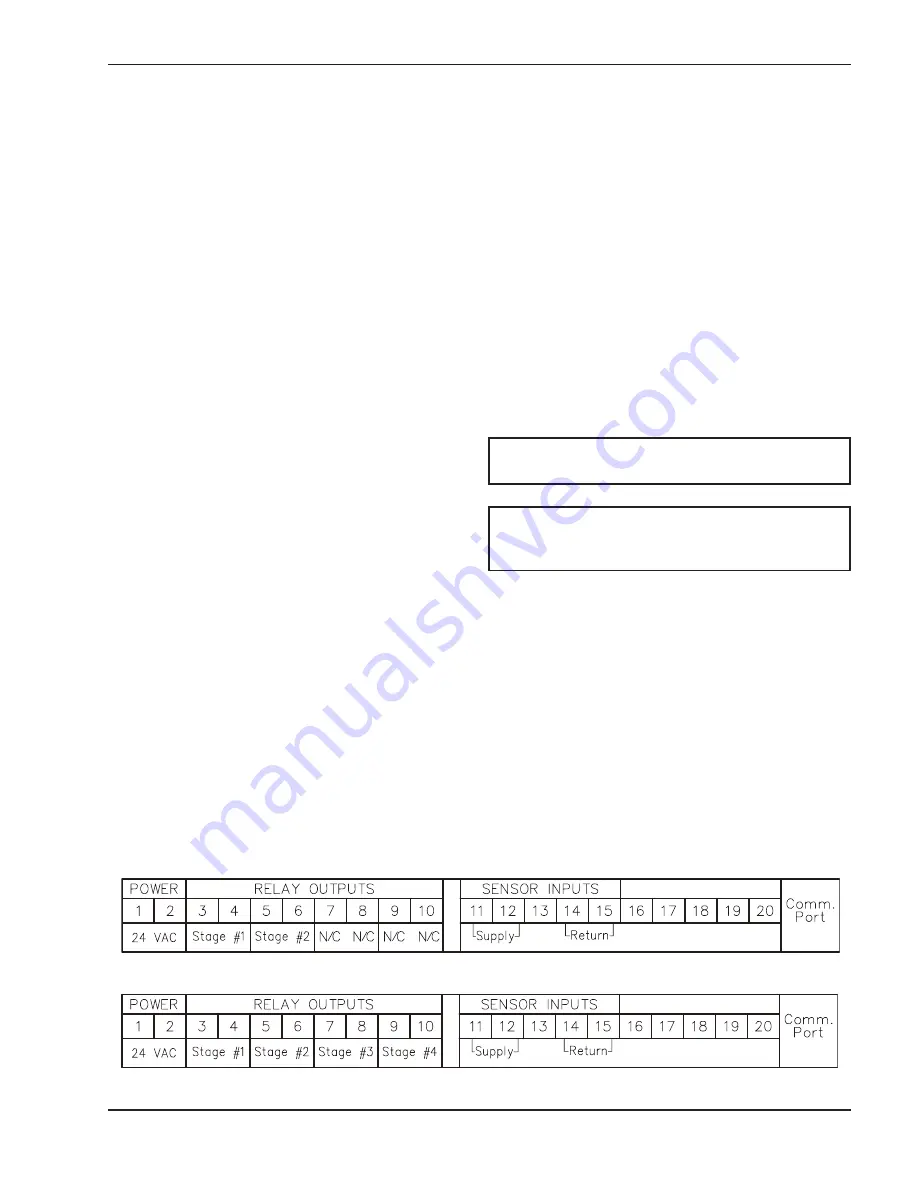

Fig. 3: Stages and Sensor Connections

2-Stage Control

4-Stage Control