Installation

2–18

F232048

Mechanical Installation (Continued)

4.

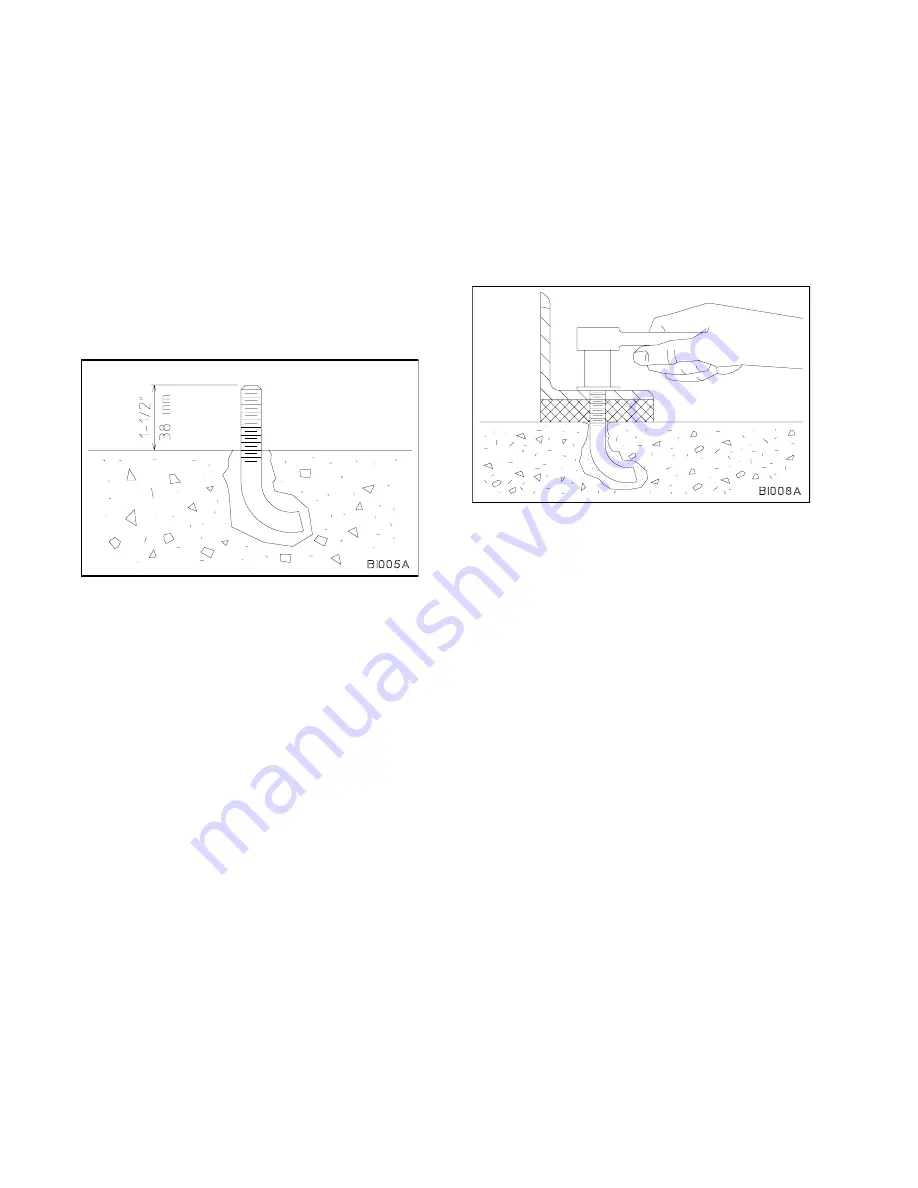

Remove debris from hole. Anchor J-bolt in

place, using “Sulfaset” anchoring

compound or equivalent; verify that the J-

bolts are in the correct locations and that

1-1/2"

(38 mm) of each J-bolt protrudes from the

floor. See Figure 2–20.

Figure 2–20.

5.

Raise and level the base frame 1/2"

(13mm) off the floor on three points, using

spacers such as nut fasteners.

6.

Fill the space between the frame base and

the floor with machinery grout; grout

completely under all frame members.

7.

Remove the spacers carefully, allowing the

base frame to settle into the wet grout.

8.

Before grout sets completely, make a drain

opening in the rear of the machine

grouting with a stiff piece of wire; this

opening should be approximately 1/2" (13

mm) wide to allow any surface water

build-up under the base of the machine to

drain away.

9.

Attach the washers and locknuts to the J-

bolts after the grout

has hardened.

10.

Tighten the lock nuts by even

increments—one after the other—until all

are tightened evenly and the base frame is

fastened securely to the floor. See Figure

2–21.

Figure 2–21.

11.

After the grout is completely dry, tighten

all of the lock nuts to

100 ft-lbs (136 N/m) torque.

12.

Position the machine over the base frame,

aligning the mounting holes on the

machine with the corresponding holes on

the frame.

13.

Install a bolt, lockwasher, and nut in each

mounting hole. Use 5/8–18x2" grade 5

mounting bolts with 5/8–18" grade B nuts

and 5/8 lockwashers.

14.

Handtighten each nut.

15.

Tighten the two rear nuts two turns.

16.

Tighten the two front nuts two turns.

17.

On 160s and 230s, firmly tighten the two

middle nuts.

18.

Tighten the two front nuts firmly.