1–5

Safety

F232048

Temperatures above 120° F (50° C)

will result in more frequent motor

overheating and, in some cases,

malfunction or premature damage to

solid state devices that are used in

some models. Special cooling devices

may be necessary.

•

Humidity

. Relative humidity above

90% may cause the machine’s

electronics or motors to malfunction

or may trip the ground fault

interrupter. Corrosion problems may

occur on some metal components in

the machine.

If the relative humidity is below

30%, belts and rubber hoses

may eventually develop dry rot.

This condition can result in hose

leaks, which may cause safety

hazards external to the machine

in conjunction with adjacent

electrical equipment.

•

Ventilation

. The need for make-up air

openings for such laundry room

accessories as dryers, ironers,

water heaters, etc., must be

evaluated periodically. Louvers,

screens, or other separating

devices may reduce the available

air opening significantly.

•

Radio Frequency Emissions

. A filter

is available for machines in

installations where floor space is

shared with equipment sensitive to

radio frequency emissions.

•

Elevation

.

If the machine is to be

operated at elevations of over 3,280

feet (1,000 meters) above sea level,

pay special attention to electronic

settings (particularly temperature)

or desired results may not

be achieved.

•

Chemicals

. Keep stainless steel

surfaces free of chemical residues.

•

Water Damage

.

Do not spray the

machine with water. Short circuiting

and serious damage may result.

Repair immediately all seepage due

to worn or damaged gaskets, etc.

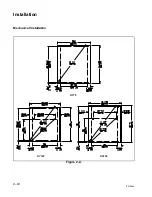

Machine Location

•

Foundation

. The concrete floor must

be of sufficient strength and

thickness to handle the floor loads

generated by the high extract speeds

of the machine.

•

Service/Maintenance Space

. Provide

sufficient space to allow comfortable

performance of service procedures

and routine preventive maintenance.

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel reducers,

carbon tetrachloride, gasoline, benzene,

naptha, etc. Doing so could result in serious

personal injury and/or damage to

the machine.

SW002

DANGER