V1.0

RayToos AG. © Copy Right

www.raytools.ch

BM110 SERIES (Chinese Model) 3.3KW Auto Focus Laser Cutting Head

-

User Manual

10 | 20

3.1.2

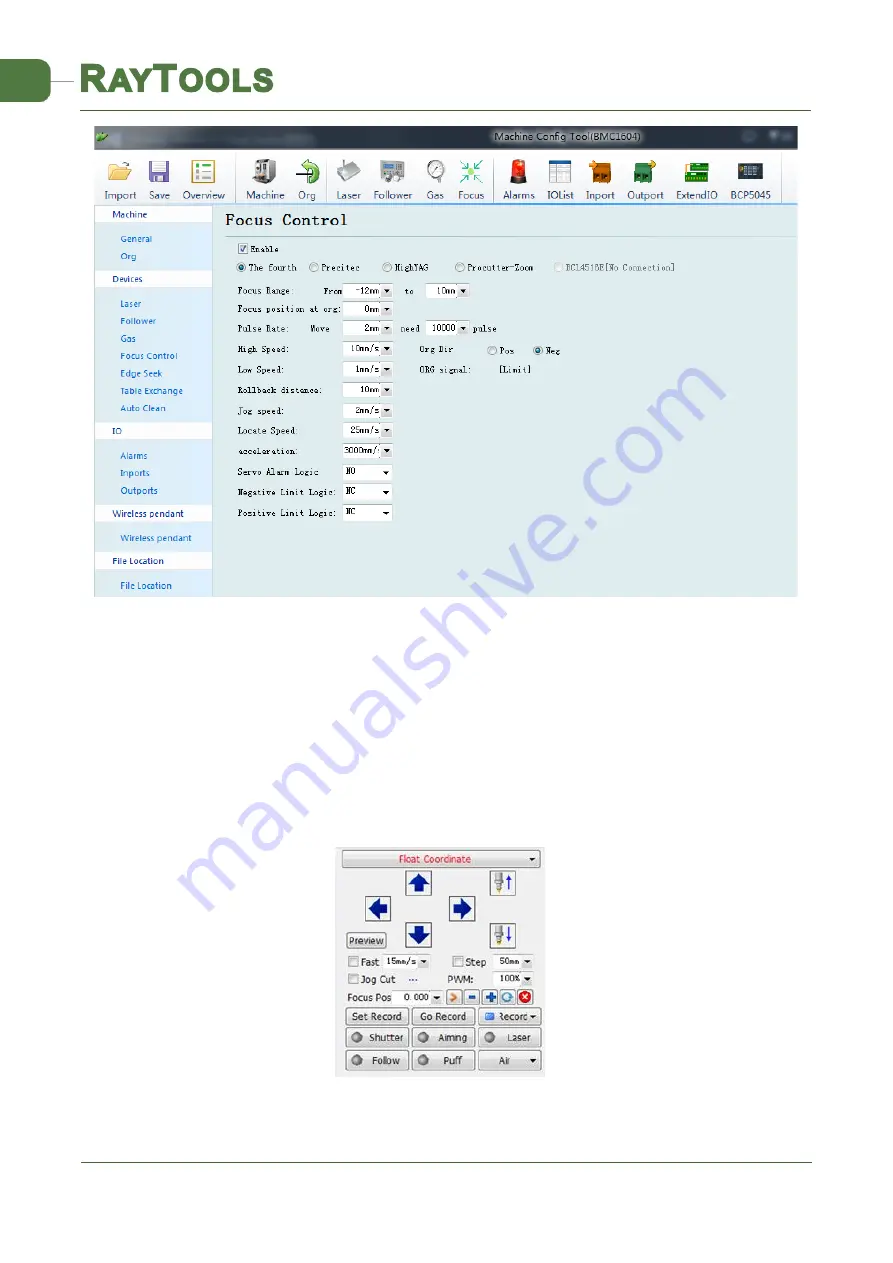

Interface Operation

1.

Move J axis to check if the action is normal (“thread pitch” and direction), J+ indicates

scale 0+.

2.

Slowly moving the J axis so that it meets the positive and negative limit, check whether

the direction and limit signal are normal or not.

3.

By click homing icon, J axis moves to negative direction and do 2

nd

homing when

touches negative limit. In this case the position of zero point coincides with zero focal

position. The homing is finished.

Note:

1.

Click+, the lens holder moves upward. When it touches positive limit, click

-

, then lens

Figure 4.6— Operation

interface