V1.1

Shanghai Empower Technologies Co., Ltd. © Copy Right

www.empower.cn

BM114 SERIES 6KW Laser Cutting Head User Manual

16 | 11

Note:

1. Click+, the barrel move upward. When it touches positive limit, click -, then barrel move downward to

the negative limit.

2. The direction of origin is negative, and take lower limit as a sampling signal.

3. Pitch 2mm, 10000 pulses one turn

4.

Positioning speed recommended setting 50-100mm/s.

3.3 BC with velocity mode

3.3.1

Distribution

1. AheadTechs DC motor :

The motor is DC servo motor, which should connect the end of the drive L1, L2 respectively with+24V

and 0V , and the driver power supply L1C and L2C should connect to 220V exchange L and N.(24V power

supply is customer-owned)

2. Limit Signal:

Black

White

Brown

Blue

Lower limit

Upper limit

+24V

0V

Note: the limit sensor is active low, and the signal is often closed, and it continuously outputs 0V signal

when it is not triggered. The limit diagram is shown in Figure 4-1.

3.3.2

Software settings

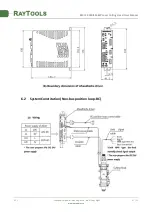

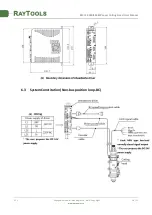

The axis parameter settings are shown in Figure 4.8.

Entry J axis detection, “closed loop movement control”, inch J axis, detect whether the action is nomal,

0

scale moving upward is J+, encoder and speed detection.