V1.1

Shanghai Empower Technologies Co., Ltd. © Copy Right

www.empower.cn

BM114 SERIES 6KW Laser Cutting Head User Manual

8 | 11

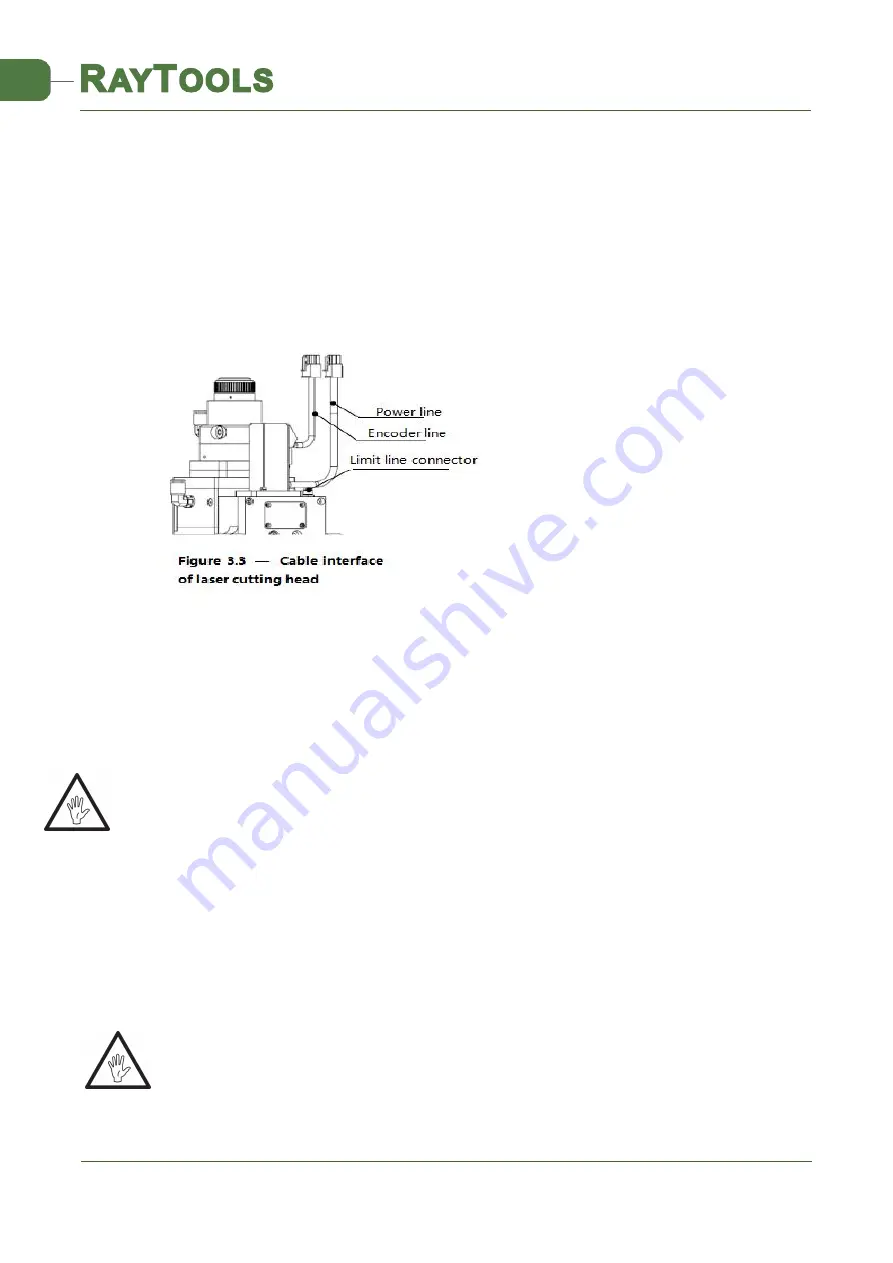

2.3 Connection of Cutting Head Cable

This paper mainly introduces the connection between the cable and the cutting head. The control section of

the driver and the connection refer to the wiring diagram of each series of system.

2.3.1

Connection of Cutting Head and Cable

Connect the corresponding connector of cutting head with motor power cable, encoder cable, sensor cable

respectively (as shown in figure 3.3). After the proper length is reserved, the cable is inserted into the track groove

of the machine tool and fixed.

2.3.2

Cable Connection and Driver Connection

Connect motor power wire and encoder wire with the corresponding interface of driver according to the

definition in cable sleeve. The wiring of the drive and limit sensor cables is shown in the wiring diagram of the

various wiring systems attached.

Caution: The limiting sensor is divided into high level output and low level

output, and the two are normally closed output mode(high level and low level signal are output by the sensor

when not triggered); electric relay should be self installed when necessary to carry on the high-low level or the

normally open and normally closed conversion.

CAUTION:

All wiring is in the state of power failure, and the power can be debugged after inspection.

2.4 Fiber Input Interface

BM114 is suitable for most industrial laser generators. It is equipped with collimating mirror assembly

The connection between the end of the fiber and the cutting head is called fiber interface. Commonly used

fiber connectors include QBH, QD, etc, and every fiber interface has its unique fixation method. Please refer to

corresponding instruction of fiber interface. Figure 5 shows the installation interface of QBH connector.

WARNING:

The optical devices must be kept clean and all dust must be removed before use. If the laser

head is vertically inserted in the optical fiber, the laser head must be rotated 90 degrees to the

horizontal level and then inserted into the optical fiber to prevent dust from entering the interface and

falling on the surface of the lens. Upper limitng in the fiber before fixing the laser head.