1/20/2015 (3:46 PM)

2034vx & 2034vxa v6.0.doc

3.3

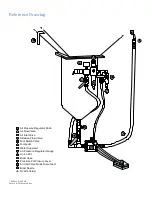

Pressurizing the Pressure Pot

The pressure pot opening is located inside the

cabinet below the metal grate. The pressure pot

closure cap is attached to a linkage, which is

movable from the pressure pot closure lever (L) on

the left side of the cabinet. The purpose of the lever

and linkage is to lift the pressure pot closure cap

upward to contact the pressure pot rubber seal

located at the top of the pot. While holding the cap

in the up position with lever (L) the air is turned on,

this fills the pot, and presses the cap securely

against the pressure pot rubber seal, sealing the pot

and pressure inside. When the cap is in the down

position there is a gap between the cap and the seal,

which allows the abrasive from blasting to re-enter

the pot.

! WARNING

Ensure that the Blast Hose (K) is in the cabinet at

all times when the pressure pot is under pressure.

3.3.1

Locate the Pressure Pot Closure Lever (L) and

move it back and forth rapidly several times to

shake off any abrasive that may be sitting on top of

the closure cap.

3.3.2

Now push the lever away from you to lift the

pressure pot closure cap against the rubber seal.

While holding the lever firmly in this forward

position, open the Air Inlet Valve (C). Count 3

seconds and then release the Pressure Pot Closure

Lever (L). The pot should be closed and

pressurizing at this point. The Air Pressure

Regulator Gauge (H) should rise to the factory pre-

set blasting pressure of 30 psi.

3.3.3

NOTE

: If you hear air escaping inside the

cabinet, turn off lever (C) and try again. If for some

reason you cannot get the pressure pot closure cap

to seal, call Rayzist and ask for technical help.

3.4

Adjusting Blasting Pressure.

3.4.1

After pressurizing the pot the pressure

regulator gauge (H) should read about 30 psi. If the

gauge has a different reading make an adjustment as

follows: Unlock the Air Pressure Regulator Knob

(A) by pulling upwards. Twist clockwise to

increase blast pressure or counter clockwise to

decrease blast pressure. Set regulator to desired

pressure, and then press down to lock the knob.

3.5

Adjusting Abrasive and Air flow

3.5.1

Turn on the dust collector and lights and check

the plastic dust bag on the dust collector to make

sure it is collapsing; this indicates it is properly

installed and has sealed the dust collector opening.

! NOTICE

When first stepping on the Foot Pedal (F), you may

experience a thick burst of abrasive media from the

blasting tip, which should smooth out to a constant

flow of abrasive and air. This occurs when Abrasive

Flow Valve (D) is open too far. When starting to

blast you should hold the blasting tip away from the

item you are blasting until abrasive media is

flowing smoothly.

3.5.2

Put on the rubber blasting gloves and hold the

Blast Hose (K) and have the tip pointing

downwards towards the grate about 6" to 8" away.

Step on the foot pedal and watch the flow of

abrasive as described above.

! NOTICE

Air Flow Valve (B) adjusts how much air pushes

the abrasive through the Blast Hose (K). Less air

flow = more abrasive. More air flow = less

abrasive.

3.5.3

If necessary adjust Air Flow Valve (B) to

achieve the proper balance of abrasive and air. If

there is too much abrasive open valve more, if not

enough close the valve slightly. If the abrasive is

pulsating between thick and thin, you may need to

slightly close the Abrasive Flow Valve (D).

3.6

Sandcarving

3.6.1

Turn on cabinet power switch located above

the right cabinet access door; the dust collector and

lights should both begin operating.

3.6.2

Use (provided) rubber gloves before blasting.

(18mil or thicker rubber or latex safety gloves can

be purchased from a local hardware store.).

Summary of Contents for 2034vx

Page 1: ... 2034vx 2034vxa Sandcarving System ...

Page 2: ......

Page 19: ......

Page 20: ...RAYZIST COM 800 729 9478 ORDER ONLINE WWW RAYZIST COM STORE ...