1

CONTENTS

Introduction ................................. 1

Maintenance .................................... 8

Assembly ..................................... 2

Troubleshooting .............................. 8

Nozzle selection .......................... 2

To replace the piston seal ................ 9

Strap adjustment .......................... 3

Trigger valve maintenance ............. 10

Calibration ................................... 3

Accessories .................................... 11

Mixing and filling ....................... 5

Parts diagrams ........................... 12-13

Spraying ...................................... 6

Parts list .......................................... 14

After spraying ............................. 7

Calibration working sheet .............. 15

INTRODUCTION

The

SA15

is a quality knapsack sprayer suitable for a wide range of agricultural and

horticultural uses. The sprayer is designed to be robust and easy to maintain and

features an internal piston pump and pressure cylinder for maximum protection,

comfortable shoulder straps, a waist strap for ease of extended use, a wide neck and

filter for safety of filling operations and a 15 litre tank designed so that it is held away

from the operator's back for both increased safety and comfort. The sprayer can be

used with either right or left hand lever.

Designed for the application of herbicides, insecticides and fungicides the sprayer is

supplied with a range of nozzles suitable for most spray operations.

This manual is designed to help you get the most from your

SA15

Sprayer and

MUST

BE READ

before using the sprayer for the first time

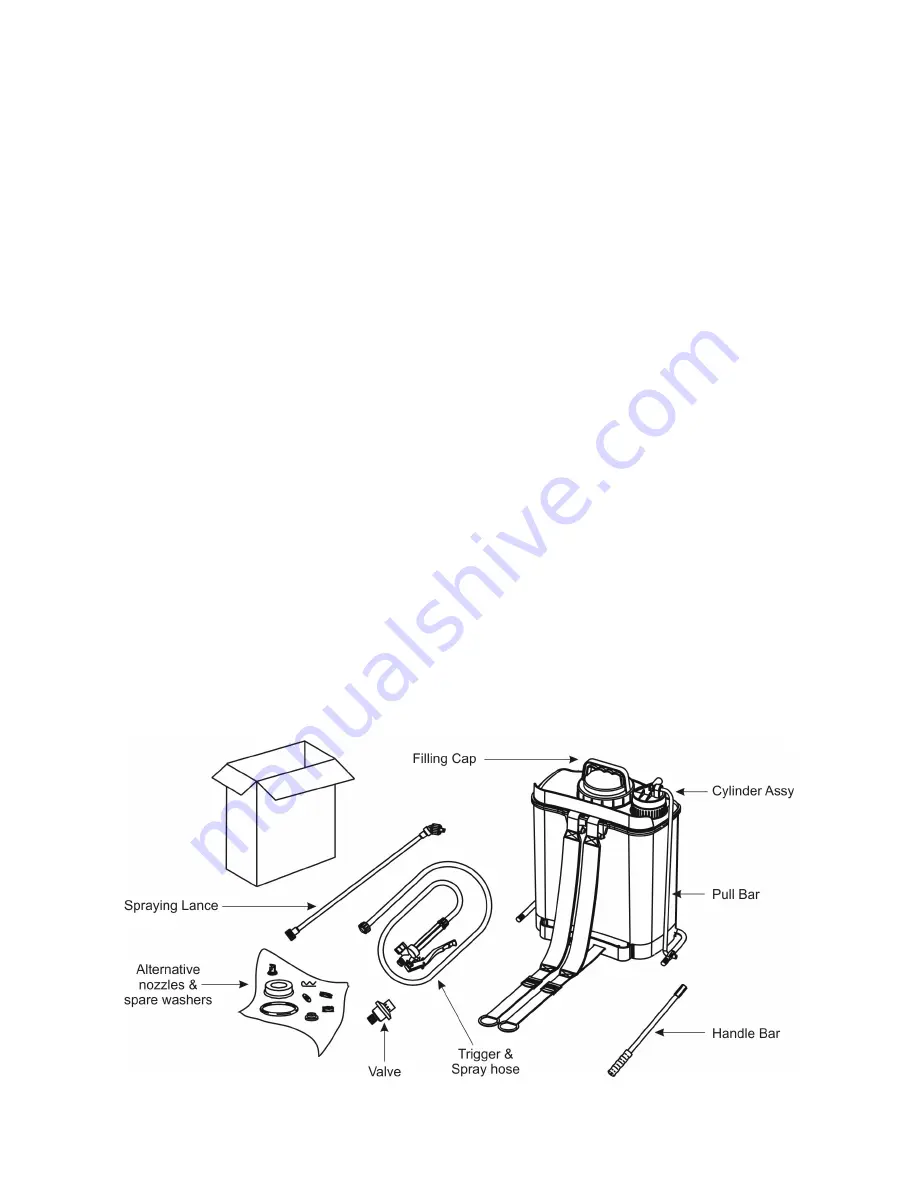

When the

SA15

is new it needs to be unpacked and assembled for use. Check that you

have all the components as shown below.